Suppliers News

Dong Tien successfully starts up its third Andritz OCC line

Dong Tien-Long An Paper JSC has successfully started up a recycled fiber line at its board production mill in Tay Ninh Province, Vietnam. This new OCC (old corrugated containers) line, the third supplied by international technology group ANDRITZ, is designed to process 330 t/d of mixed OCC for the production of high-quality testliner serving both domestic and export markets. The addition of this third line is a strategic step that increases Dong Tien’s production capacity, further enhances pulp quality, and strengthens its commitment to sustainable growth and operational excellence.

Smarter batch automation Valmet FlexBatch is now available for Valmet DNAe Distributed Control System

Valmet expands its automation solutions portfolio in the process industries and announces the release of Valmet FlexBatch® 8, the latest version of its advanced batch automation and recipe management software. Valmet FlexBatch was originally developed for Valmet D3 automation system and with the newest version, it is fully integrated both with Valmet DNAe and Valmet D3 automation solutions.

So that pumping doesn’t feel like hard work

Handling lubricating grease can be a physically demanding task for maintenance engineers. This is especially true when thick grease has to be delivered using ergonomically unfavourable hand pumps. The Lutz Lube Drive filling tool, which can be powered by a cordless screwdriver, provides relief. It will be on display from 25 to 26 February at the Pumps & Valves 2026 trade fair in Dortmund (Hall 7, Stand 7228). Lutz Pumpen will also be showcasing the Battery B2 mobile drum pump, designed to make transferring liquids from canisters and hobbocks easier.

Kesla Oyj expands its range of small harvester cranes

Kesla Oyj is expanding its small harvester crane product line by introducing new, more versatile HF versions. The updated 6H series meets the growing demand for lightweight thinning machines and offers manufacturers an even more durable crane solution with improved operating characteristics.

Valmet launches new Bioneer press roll covers with reduced climate impact

Valmet continues to lead the way towards circularity by introducing Bioneer press roll covers. The new innovative press roll covers are manufactured by applying recycled, renewable and bio-based raw materials, thereby enabling Valmet and its customers to reduce reliance on fossil resources.

MM Group orders continuous cooking plant from Andritz

International technology group Andritz has received an order to supply a new cooking plant to MM Group’s integrated pulp and paper mill in Kwidzyn, Poland, supporting the mill’s major sustainability and energy-efficiency upgrade program. Andritz will replace the mill’s batch digester cooking plant with a LoSolids continuous cooking plant designed to switch between softwood and hardwood pulp production. This investment will significantly reduce energy consumption and CO2 emissions at the MM Kwidzyn mill.

IBS Group successfully commissions starch preparation plant at Mondi Štĕtí

PGA Anlagenbau, a member of the IBS Paper Performance Group, is celebrating the successful commissioning of a complete starch plant for mass starch preparation at Mondi Štetí, Czech Republic. The plant is destined for the state-of-the-art new paper machine, which went into operation in December 2024. An essential component of the plant is the patented starch cooker PGA starchPerformer.

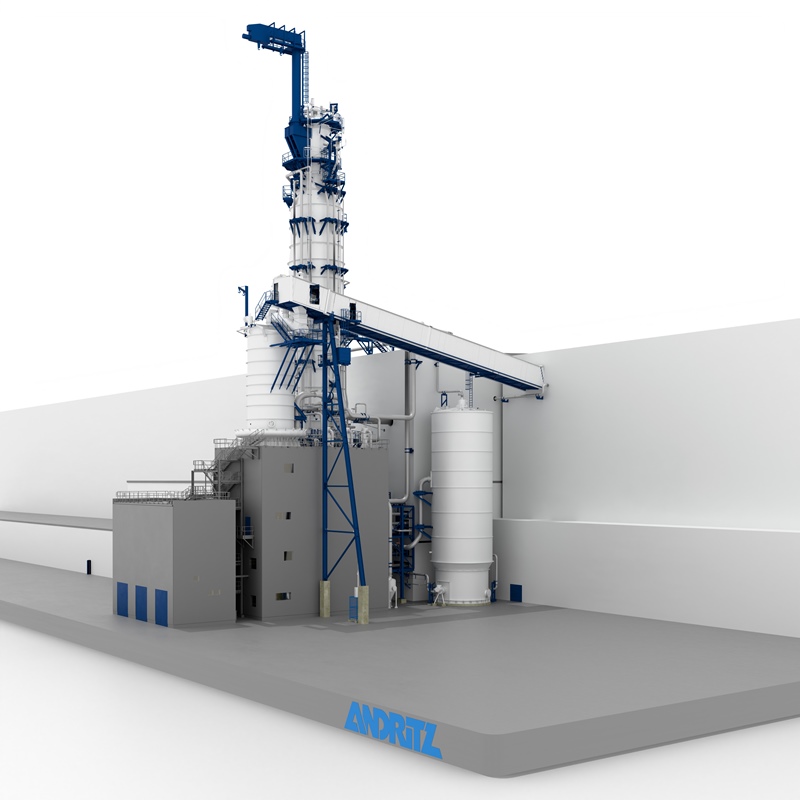

Andritz starts up sludge drying plant at Eldorado Brasil Celulose

International technology group Andritz, which supplied the technology and developed the new biological sludge drying plant for Eldorado Brasil Celulose’s pulp mill in Três Lagoas, Brazil, celebrated the plant’s successful start of operations. This project represents another step forward in Eldorado’s strategies to transform waste into energy and enhance the environmental efficiency of its operations.

Valmet to acquire Severn Group to strengthen Process Performance Solutions segment

Valmet has entered into an agreement to acquire Severn Group (“Severn”), a well-established industrial valve company, from Bluewater, a UK-based private equity firm. The acquisition covers all three Severn divisions: Severn Glocon, ValvTechnologies, and LB Bentley. Severn serves process industries globally and has over a 60-year track record of delivering specialized flow control solutions across the most demanding applications. Severn’s strong technologies, installed base and customer relationships with a diverse set of the world’s largest blue-chip industrial companies support Valmet’s growth strategy beyond its traditional core biomaterials business.

Toscotec starts-up PM5 tissue line for Saudi Paper Group in Saudi Arabia

Toscotec is happy to announce the successful start-up of the PM5 tissue line at Saudi Paper Group’s facility. This turnkey project follows the supply of a complete AHEAD 2.2S line in 2022. This massive undertaking represents a complete turnkey project, encompassing everything from the advanced stock preparation system and detailed mill engineering, to the complete erection and final start-up assistance – underscoring the comprehensive nature of the partnership and the scale of the installation.

Voith wins German Sustainability Award for closed recycling loop of Infinity press felts

Technology company Voith has won the German Sustainability Award for its Infinity +Green press felt and the recycling concept behind it. The 18th annual award ceremony took place on December 5, 2025, in Düsseldorf. Voith was among the winners in the “Resources” category and impressed the 240 jury members from science, business and civil society with its innovative press felt for paper production. The full recyclability of the product in a closed cycle, which is a first, contributes to improving the sustainability of industrial paper production.

Next-generation Valmet IQ Web Monitoring System for process visibility

Valmet introduces the renewed IQ Web Monitoring System (WMS), designed to elevate quality and efficiency in pulp, paper, tissue, as well as paper and board converting industries. The new WMS delivers exceptional image quality through the most compact design and industry-leading illumination technology.