Manufacturer News

Holmen: Repurchase of shares

The Board of Directors of Holmen has decided to exercise its authorisation from the Annual General Meeting held on 31 March 2025 to buy back own shares.

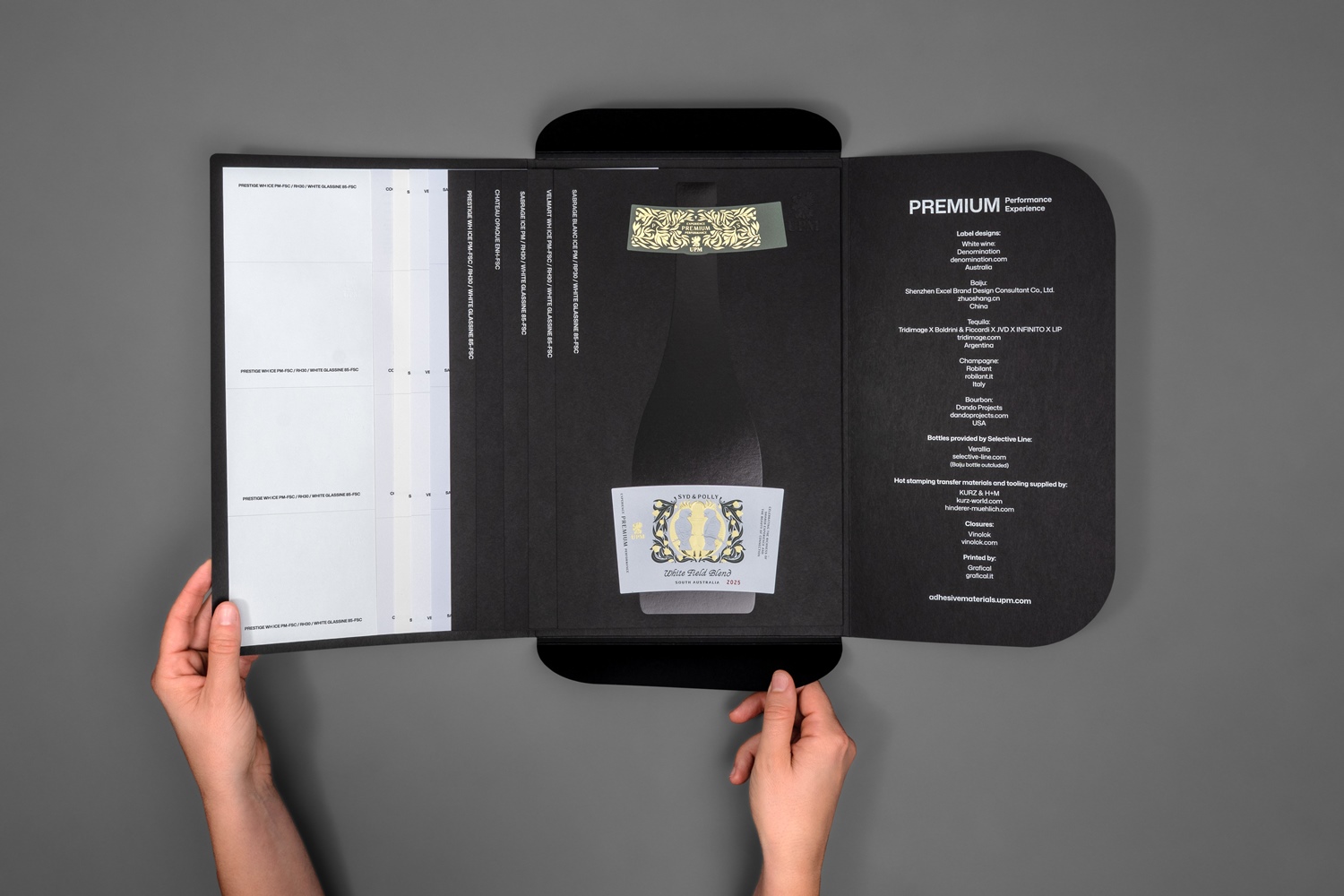

UPM Adhesive Materials unveils a global showcase of premium performance label materials for wine and spirits

UPM Adhesive Materials unveils a curated collection of Premium Performance label materials for wine and spirits packaging. Each material has been selected for its advanced converting properties, exceptional performance in the wine and spirits sector and ability to elevate brand and consumer experience. The collection is featured in a new sample folder, available in European, North American, South American and Asia-Pacific markets.

Oppboga Bruk collaborates with Stora Enso on EnsovelvetTM

Stora Enso is collaborating with Oppboga Bruk AB, producer of multiply paperboard for signs, displays and packaging, for the lamination and sale of Stora Enso’s newly launched Ensovelvet™ – an uncoated solid bleached sulphate board.

Holmen wins in tax case

The Administrative Court in Stockholm has granted Holmen the right to tax deductions linked to the Group's previous operations in Spain. The decision will have a positive impact on the Group's profit after tax of approximately SEK 400 million in the third quarter.

Holmen Invercote Touch in full bloom

Holmen Invercote Touch, the latest member of the iconic Invercote family, is a welcome addition for brands that want to create premium packaging products with a natural look and feel. To showcase its possibilities, Holmen has created a product sample shaped like a flower. It’s an explosion of colour, design and special effects – and shows off the paperboard’s unique tactile qualities.

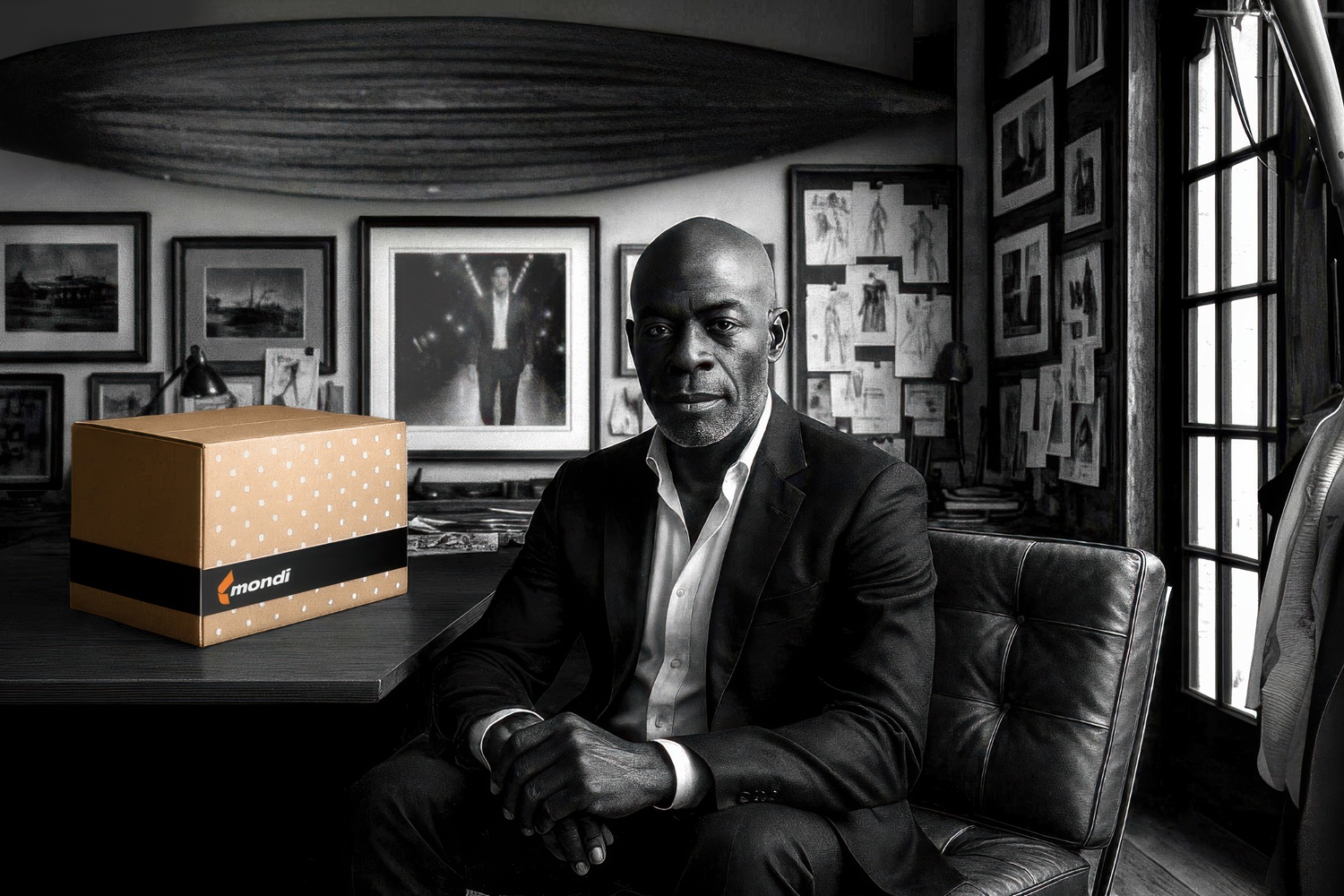

Mondi steps onto the fashion runway, introducing Fashionverse

Mondi is taking centre runway in the world of fashion eCommerce with the launch of its new marketing campaign 'Mondi Fashionverse’. With sustainable eCommerce packaging that elevates the unboxing experience, Mondi helps fashion brands strengthen customer connections through paper-based solutions that ensure product protection and efficiency across the fulfilment chain.

UPM Adhesive Materials receives RecyClass recognitions

UPM Adhesive Materials has received recognitions from RecyClass for its releasable general purpose RW85C adhesive. In addition to the previously acquired approvals, label materials with RW85C adhesive are now recognized to be releasable in the HDPE (High Density Polyethylene) container recycling and alkali/water releasable adhesive in the PET bottle recycling1. This means that the approved label materials can be recycled in HDPE natural and white and PET bottle recycling streams, further enhancing recyclability and supporting the circular economy.

Holmen Board and Paper launches next generation lightweight kraftliner

Holmen Elevate is the “lightest kraftliner on the market”, available in 72, 82 and 92 gsm. The kraftliner is well suited for e-commerce, shelf-ready and food packaging applications where both sustainability and performance are essential.

Labelexpo

UPM Adhesive Materials showcases its solutions for label material performance at Labelexpo Europe 2025

UPM Adhesive Materials, formerly known as UPM Raflatac, has announced the launch of a range of specialist solutions that address key trends in Logistics and Durables. These, together with other innovations, will be presented on its stand (3D29) at the forthcoming Labelexpo Europe show, taking place in Barcelona from 16th to 19th September. This event marks UPM Adhesive Materials’ debut under its renewed brand identity, reflecting its commitment to adhesive material expertise, sustainability and helping customers renew the everyday with label material performance.

Mondi’s paper-based CompressWrap sets new standards for Ekornes’ mattresses

Mondi is partnering with Ekornes, one of the Nordic region’s largest furniture producer, to introduce an innovative paper-based packaging solution for wrapping high-end mattresses, replacing the previous plastic solution.

Feldmuehle successfully implements restructuring measures

Following intensive discussions with the works council, Feldmuehle has implemented the planned restructuring measures. Key elements of this reorganisation include adjustments to production capacities, changes to management and the shift system. The aim of these measures is to ensure better planning, greater reliability and punctuality for customers, suppliers and the company – without compromising on product quality.

Sappi Europe announces price increase for woodfree coated papers in export markets

To support margin recovery, Sappi Europe will start implementing price increases initially USD 60-100/to, or equivalent, on all Woodfree Coated paper grades across its export markets for deliveries from 1. October 2025. The only exception is the United States, where the company has already informed customers of its intention to pass on the full cost of applicable tariffs.