News

Yarn spinning partner Tearfil continues to support Spinnova’s fibre and technology

Spinnova Plc has signed non-binding Letter of Intent (LOI) with Portuguese yarn spinning company, Tearfil Textile Yarns to secure access to Spinnova® fibre volumes. The LOI outlines an important step in Spinnova’s ambitions to create an ecosystem (consortium) to enable the availability of textile materials with sustainable Spinnova® fibre in the textile materials market.

Kesla sells the product rights of its previously discontinued wood chipper product group

Kesla announced in June 2025 that it had decided to discontinue its wood chipper product group as part of the company's strategic review. At the same time, the company initiated a sales process for the product rights related to wood chipper products. On 17 December 2025, Kesla signed an agreement to sell all product rights related to wood chipper products to the Lithuanian mechanical engineering company UAB Ukmergès Staklès.

Andritz starts up sludge drying plant at Eldorado Brasil Celulose

International technology group Andritz, which supplied the technology and developed the new biological sludge drying plant for Eldorado Brasil Celulose’s pulp mill in Três Lagoas, Brazil, celebrated the plant’s successful start of operations. This project represents another step forward in Eldorado’s strategies to transform waste into energy and enhance the environmental efficiency of its operations.

Emtec Electronic celebrates 30 Years of innovation, precision and global partnerships

Emtec Electronic GmbH, offering measurement solutions for the paper, nonwovens and textile industries, proudly celebrates its 30th anniversary this year. Since its founding on December 19, 1995, with just four dedicated employees, the company has grown into a globally recognised specialist headquartered in Leipzig, supported by a network of more than 30 international representatives.

Kemijarvi Biorefinery appoints Dr. Markku Hämäläinen to its Board of Directors

Kemijarvi Biorefinery Ltd. is pleased to announce the appointment of Dr. Markku Hämäläinen as a new member of its Board of Directors, effective 1 January 2026. Dr. Hämäläinen brings decades of international leadership experience in the forest industry, paper and board manufacturing, and large-scale industrial transformation.

Valmet to acquire Severn Group to strengthen Process Performance Solutions segment

Valmet has entered into an agreement to acquire Severn Group (“Severn”), a well-established industrial valve company, from Bluewater, a UK-based private equity firm. The acquisition covers all three Severn divisions: Severn Glocon, ValvTechnologies, and LB Bentley. Severn serves process industries globally and has over a 60-year track record of delivering specialized flow control solutions across the most demanding applications. Severn’s strong technologies, installed base and customer relationships with a diverse set of the world’s largest blue-chip industrial companies support Valmet’s growth strategy beyond its traditional core biomaterials business.

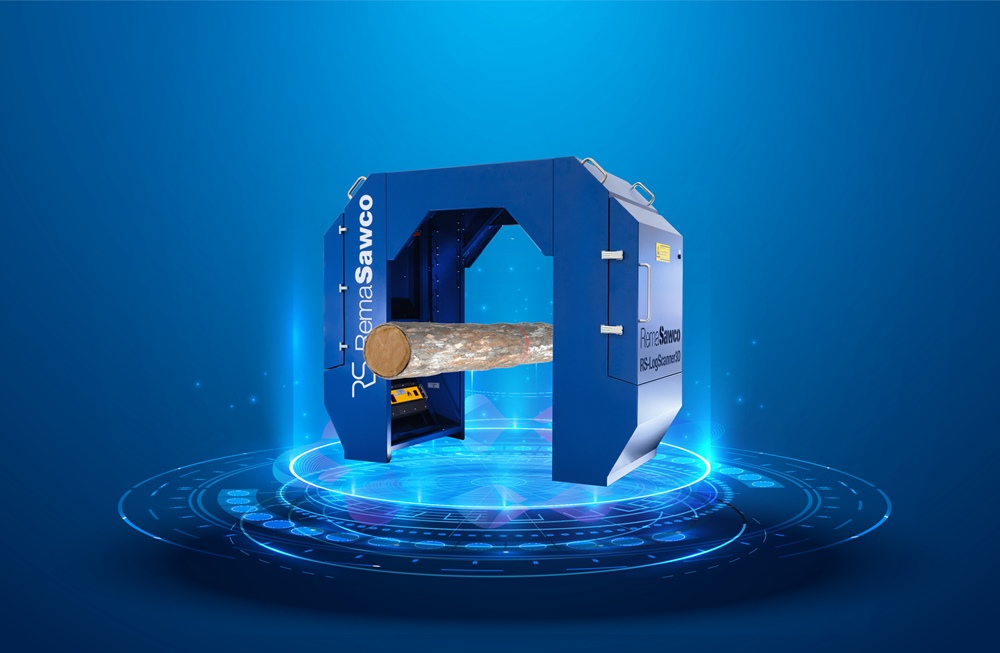

RemaSawco receives order worth just over SEK 2.4 million from Högland Anundsjö sawmill

Högland's Anundsjö sawmill and RemaSawco have signed an agreement for a comprehensive upgrade of the sawmill’s log sorting station. The total order value amounts to just over SEK 2.4 million.

Yanpai expands nonwovens capacity with two new Andritz needlepunch lines

Zhejiang Yanpai Filter Technology Co., Ltd. (hereinafter referred to as “Yanpai”) has placed an order with international technology group Andritz for two high-performance needlepunch lines. The equipment will be installed at Yanpai’s headquarters facility in Tiantai County, China. Commissioning is scheduled for the third quarter of 2026. These two lines are specially designed for the efficient processing of high-end nonwovens. They will increase Yanpai’s nonwovens production capacity and support the company’s entry into new applications.

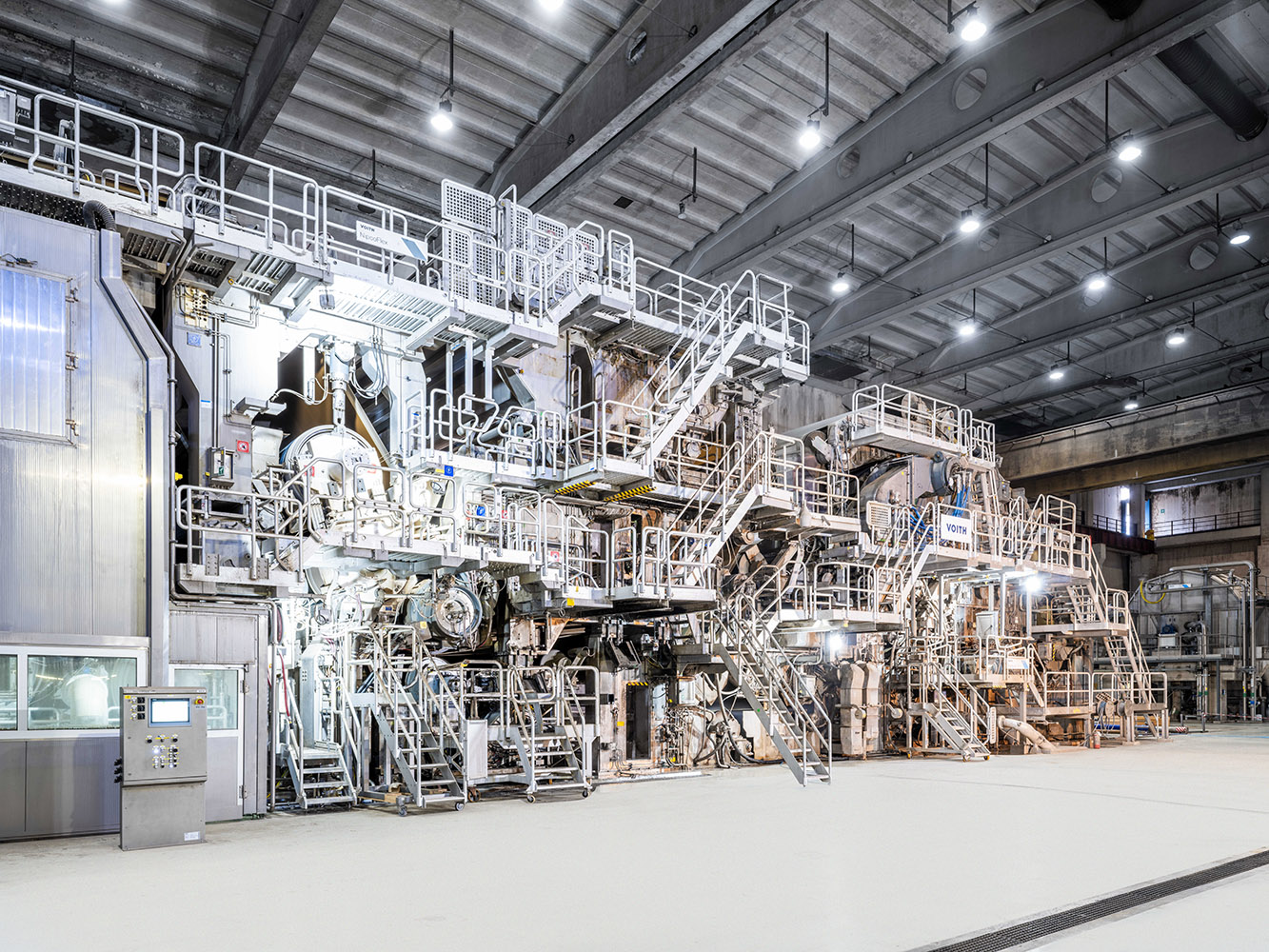

Mondi, with Voith as a key partner, brings recycled containerboard machine online

Full-line supplier Voith has supported Mondi to start up its state-of-the-art recycled containerboard paper machine in Duino, Italy, on schedule. Once fully ramped up, the machine will produce 420,000 tons of high-quality recycled containerboard annually. The mill’s product portfolio includes waste-based fluting, starting with 80 gsm, testliner from 90 gsm upwards, and paper reels from 0.95 m to 3.35 m on Mondi’s widest recycled paper machine.

Toscotec starts-up PM5 tissue line for Saudi Paper Group in Saudi Arabia

Toscotec is happy to announce the successful start-up of the PM5 tissue line at Saudi Paper Group’s facility. This turnkey project follows the supply of a complete AHEAD 2.2S line in 2022. This massive undertaking represents a complete turnkey project, encompassing everything from the advanced stock preparation system and detailed mill engineering, to the complete erection and final start-up assistance – underscoring the comprehensive nature of the partnership and the scale of the installation.

Voith wins German Sustainability Award for closed recycling loop of Infinity press felts

Technology company Voith has won the German Sustainability Award for its Infinity +Green press felt and the recycling concept behind it. The 18th annual award ceremony took place on December 5, 2025, in Düsseldorf. Voith was among the winners in the “Resources” category and impressed the 240 jury members from science, business and civil society with its innovative press felt for paper production. The full recyclability of the product in a closed cycle, which is a first, contributes to improving the sustainability of industrial paper production.

Gmund Paper wins German Sustainability Award 2026

On the 5th of December 2025, Gmund Paper received the German Sustainability Award 2026 in the paper, cardboard, paperboard category. The independent expert jury awards the prize to companies that have made a particularly impressive contribution to transformation in their respective industries, based on transparent jury rules, intensive research, publicly available information and the expertise of the jury.