News

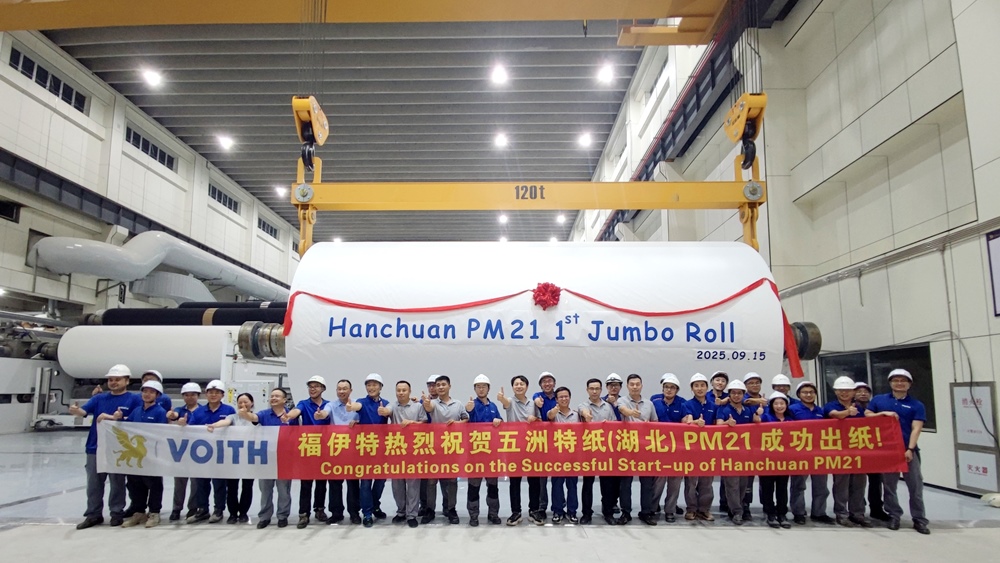

World's widest release paper production line successfully started up

Voith and Wuzhou Special Paper have successfully commissioned the new PM 21 specialty paper machine in Hanchuan, Hubei Province. It is the world's widest machine for the production of release paper. The machine, supplied entirely by Voith, demonstrates the technology group's leading role in the field of high-quality specialty papers. With a working width of 8.100 meters at the reel, the PM 21 produces around 300,000 tons of specialty paper per year with basis weights ranging from 35 to 120 g/m² – primarily lightweight release base paper.

Sappi Europe announces price increase for coated mechanical reels

Sappi Europe, producer of high-quality graphic papers, today announced a general price increase of 5-7% across its Coated Mechanical portfolio, effective from 1 January 2026. This adjustment is driven by a continued escalation in key input costs and the need to ensure the long-term financial sustainability of their operations.

Andritz strengthens boiler service business by acquiring Allen-Sherman-Hoff

International technology group Andritz has acquired Allen-Sherman-Hoff from US-based Babcock & Wilcox Enterprises, Inc., further strengthening its offering of boiler solutions and related services. The acquisition supports Andritz’s long-term strategy to grow its aftermarket and service business by offering customers complete lifecycle solutions and support.

Holmen: Repurchase of shares

The Board of Directors of Holmen has decided to exercise its authorisation from the Annual General Meeting held on 31 March 2025 to buy back own shares.

Omya launches global sales and distribution business unit for specialty materials

Omya, the global minerals and chemicals company operating in over 50 countries, has launched a new business unit specializing in the sales and distribution of specialty materials. Headquartered in Switzerland, Omya Specialty Materials combines a comprehensive portfolio of pigments, binders, additives and life science ingredients from leading manufacturers with the company’s own extensive range of mineral-based products

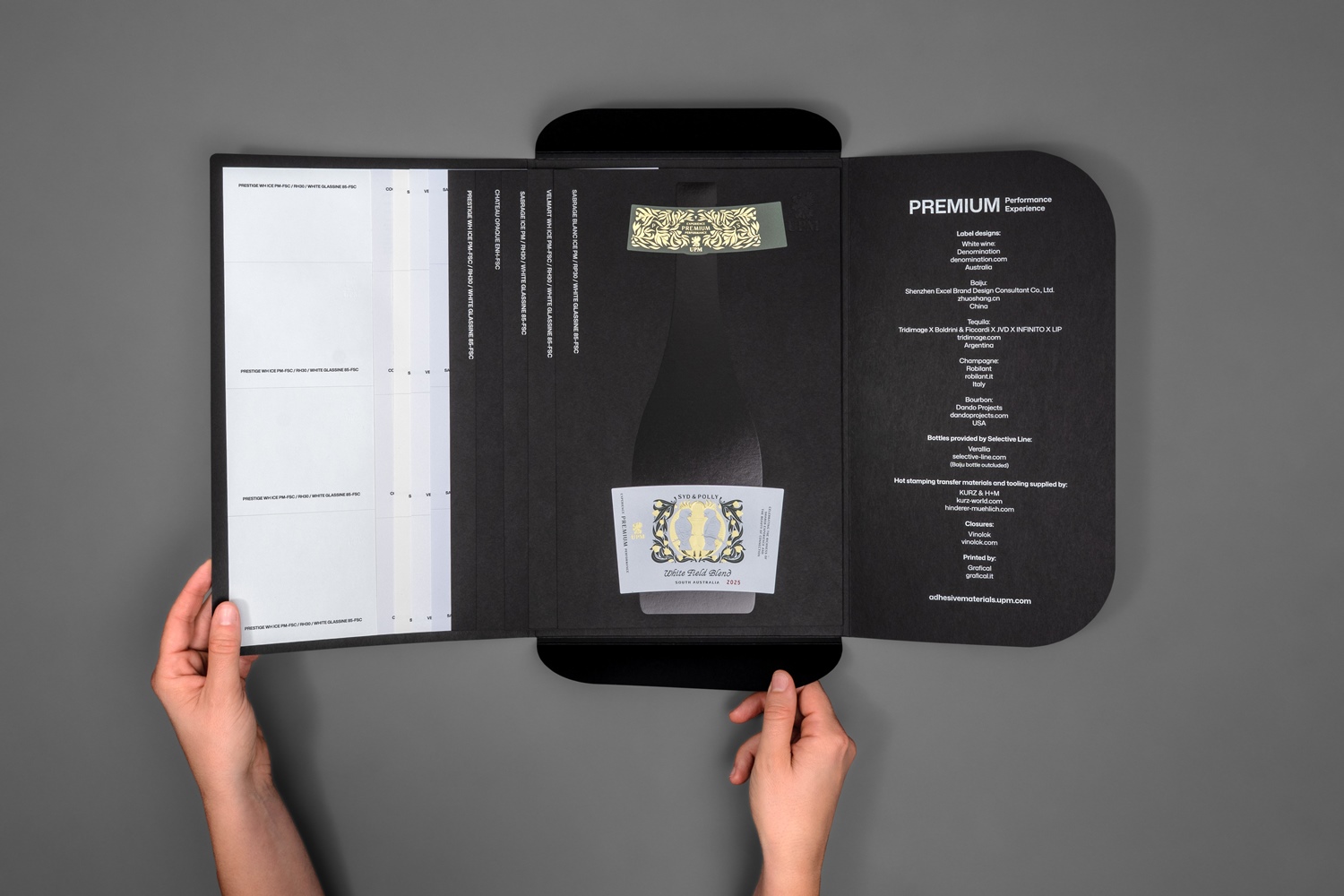

UPM Adhesive Materials unveils a global showcase of premium performance label materials for wine and spirits

UPM Adhesive Materials unveils a curated collection of Premium Performance label materials for wine and spirits packaging. Each material has been selected for its advanced converting properties, exceptional performance in the wine and spirits sector and ability to elevate brand and consumer experience. The collection is featured in a new sample folder, available in European, North American, South American and Asia-Pacific markets.

New PM 71 and PM 72 increase packaging paper production at Shanying Suzhou

Shanying Suzhou Paper has successfully started paper production on its new PM 71 in Suzhou, west of Shanghai. Together with the sister machine PM 72, which recently went into operation, this double start-up marks another milestone in the partnership between Shanying and Voith. With the new machine supplied by Voith, Shanying is significantly expanding its production capacity in the premium packaging segment. In addition, the company can respond more quickly to market developments and strengthen its position in the growing market for packaging papers.

Oppboga Bruk collaborates with Stora Enso on EnsovelvetTM

Stora Enso is collaborating with Oppboga Bruk AB, producer of multiply paperboard for signs, displays and packaging, for the lamination and sale of Stora Enso’s newly launched Ensovelvet™ – an uncoated solid bleached sulphate board.

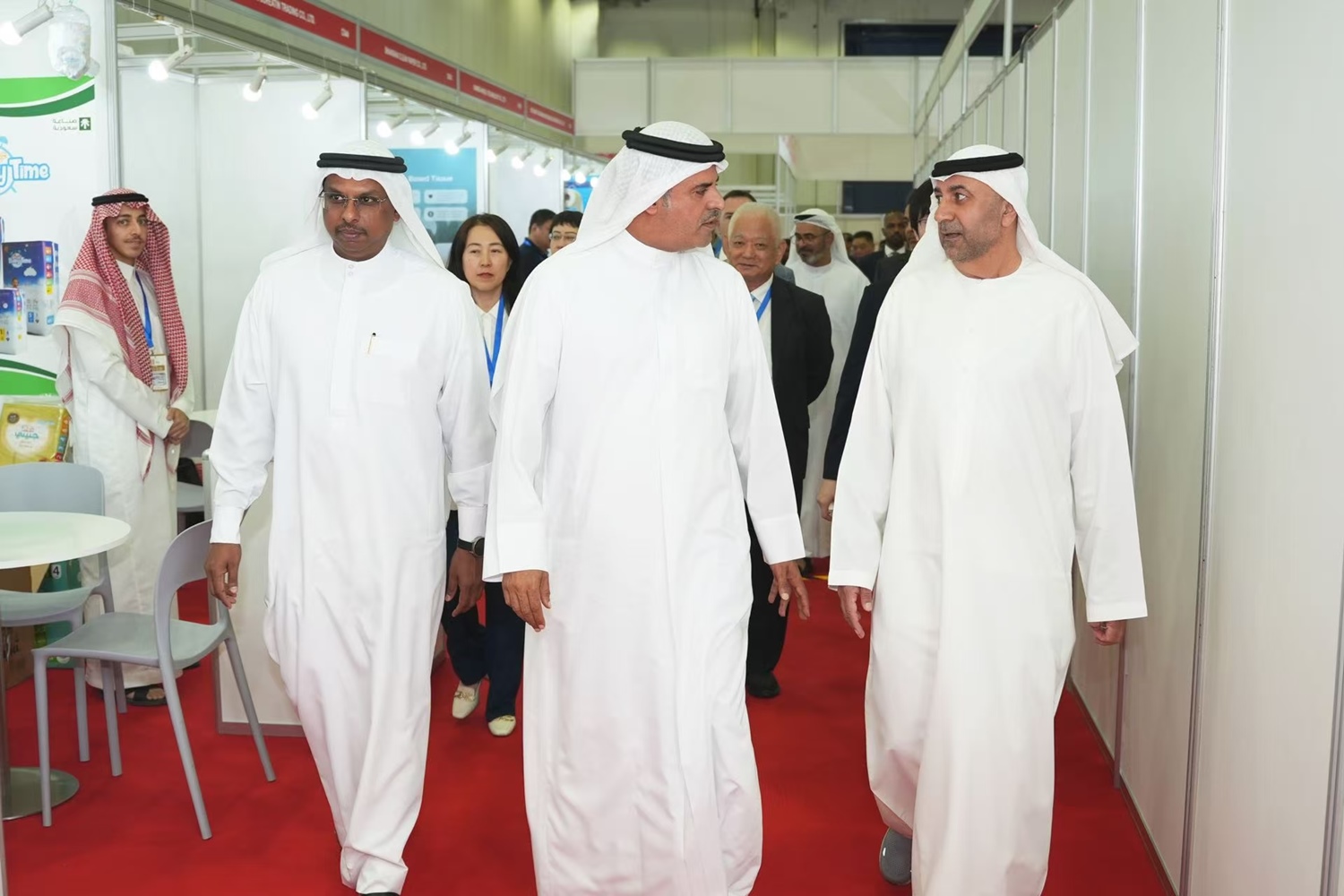

Debut CIDPEX Middle East empowers Chinese brands in high-growth MENA region

The inaugural CIDPEX Middle East exhibition, organized by China National Pulp and Paper Research Institute Co., Ltd. (hereinafter referred to as "CNPPRI"), successfully concluded alongside the Paper Arabia exhibition, hosted by Al Fajer Information & Services LLC, at the Dubai World Trade Center. The three-day event attracted over 5,000 professional visitors from over 70 countries and regions around the world, demonstrating the strong appeal of Chinese brands in the Middle East and its surrounding markets.

Holmen wins in tax case

The Administrative Court in Stockholm has granted Holmen the right to tax deductions linked to the Group's previous operations in Spain. The decision will have a positive impact on the Group's profit after tax of approximately SEK 400 million in the third quarter.

Södra adapts its organisation to strengthen competitiveness

To navigate a challenging global landscape and be better prepared for the future, Södra has initiated an action programme. The aim is to strengthen Södra’s long-term competitiveness through improved profitability and new ways of working. The planned actions will affect the entire organisation and result in 200 redundancies.

Andritz collaborates with Tandem Repeat on solutions to produce novel sustainable fiber

International technology group Andritz has entered into a collaboration with Tandem Repeat Technologies, a pioneering biotechnology company, to bring to the market industrial-scale solutions for producing ProcellTM, a new sustainable fiber for textiles and nonwovens. The collaboration brings together Tandem Repeat’s expertise in advanced biotechnology and Andritz’s extensive experience as a supplier of solutions and plants for the production of nonwovens and manmade cellulosic fibers. The two companies aim to support the textile industry’s transition toward more sustainable production and alternatives to conventional synthetic fibers.