Biofibre News

Södra tests carbon capture technology in Värö

In early 2026, a pilot project for carbon capture will be launched at the Värö industrial site. The initiative aims to build knowledge around the technology and explore new business opportunities using biogenic carbon dioxide as a raw material. The pilot is part of Södra’s long-term strategy to increase the value of every tree, strengthen competitiveness and contribute to more profitable forest estates. By testing new technology to capture biogenic carbon dioxide in an industrial setting, Södra seeks to explore how this resource can be refined and used in new applications without increasing forest harvesting.

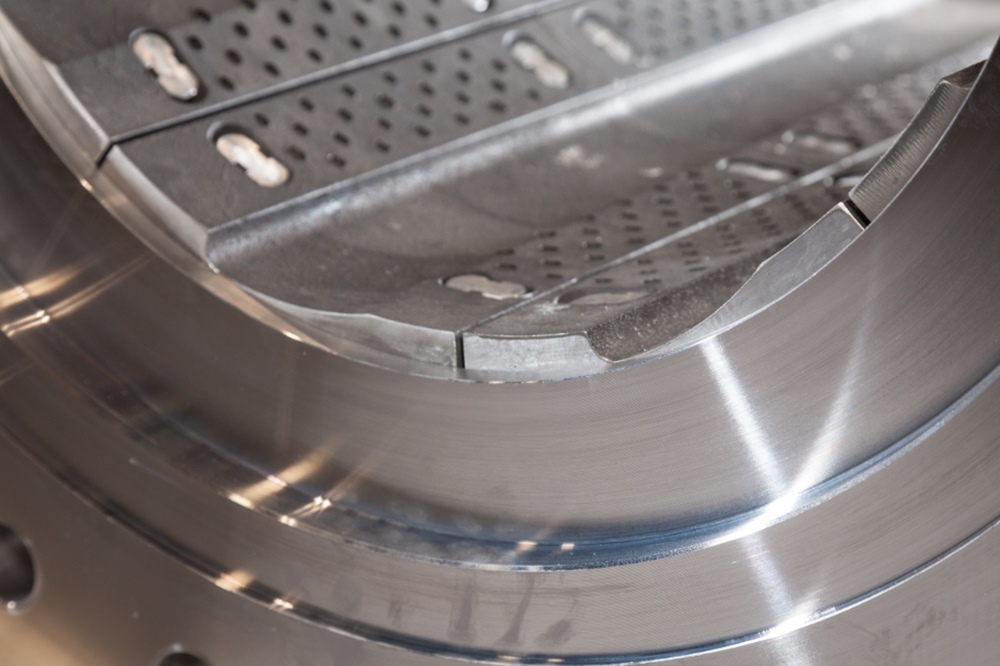

Metro Decorative places repeat order for advanced Andritz pressurized refining system

Metro Decorative Pvt. Ltd., India has placed an order with international technology group Andritz for the supply of a second pressurized refining system to its medium-density fiberboard (MDF) production facility in Kashipur, Uttarakhand. The order value will not be disclosed. It is included in Andritz’s order intake for the third quarter of 2025.

Bellmer successfully closes the acquisition of Cellwood Machinery AB

Bellmer GmbH, international supplier of paper and board machinery, is pleased to announce the successful closing of its acquisition of Cellwood Machinery AB, a glob-ally recognized Swedish manufacturer of systems for wastepaper recycling and bioener-gy pre-treatment. Following the signing of the agreement in mid-September 2025 and the completion of all regulatory and contractual conditions, the transaction was officially closed at the end of October 2025.

Södra adapts its organisation to strengthen competitiveness

To navigate a challenging global landscape and be better prepared for the future, Södra has initiated an action programme. The aim is to strengthen Södra’s long-term competitiveness through improved profitability and new ways of working. The planned actions will affect the entire organisation and result in 200 redundancies.

Andritz collaborates with Tandem Repeat on solutions to produce novel sustainable fiber

International technology group Andritz has entered into a collaboration with Tandem Repeat Technologies, a pioneering biotechnology company, to bring to the market industrial-scale solutions for producing ProcellTM, a new sustainable fiber for textiles and nonwovens. The collaboration brings together Tandem Repeat’s expertise in advanced biotechnology and Andritz’s extensive experience as a supplier of solutions and plants for the production of nonwovens and manmade cellulosic fibers. The two companies aim to support the textile industry’s transition toward more sustainable production and alternatives to conventional synthetic fibers.

Stora Enso and IUCN launch science-based framework

The partnership project between Stora Enso, the International Union for Conservation of Nature (IUCN) and Newcastle University that was initiated in early 2024 to advance positive impacts on forest biodiversity has been completed. The aim of this collaboration was to create a framework for the forestry sector to reach a net positive biodiversity impact with active forest management by reducing threats to species and conserving and restoring ecosystems.

Voith achieves Final Acceptance Certificate for Ecowipes WLM 2 in Nowy Dwór Mazowiecki

With the successful commissioning of the WLM 2 line by Ecowipes, a manufacturer of nonwoven wipes, and the receipt of the Final Acceptance Certificate (FAC), Voith reports another project success in the field of nonwoven production. This milestone marks the pinnacle of a collaborative effort to advance sustainable production in the nonwovens industry.

Södra's new electric wood chip truck goes into operation

In 2024, Södra decided to invest in an electric, heavy-duty truck to be integrated into the company's logistics chain. The vehicle is now being put into operation within the production activities, and its use will be evaluated under real conditions over two years. This initiative will reduce the environmental footprint of wood chip transports and represents an important step on Södra's path towards climate neutrality.

Mistra-Autex, Estonia, orders new needlepunch line from Andritz

Mistra-Autex AS has awarded Andritz an order to supply a complete needlepunch line for its plant in Raasiku, Estonia. The new line will produce various types of nonwovens for surface applications, 3D molding, and other technical materials, primarily for the automotive industry. Start-up is scheduled for the end of the third quarter of 2026. The value of the order will not be disclosed. It is included in Andritz’s order intake for the first quarter of 2025.