Suppliers News

MEPCO commissions Voith with construction of complete production line for recycled containerboard

Saudi Arabia’s Middle East Paper Company (MEPCO) has commissioned full-line supplier Voith with the construction of an entire production line for recycled containerboard at its Jeddah mill. The state-of-the-art and highly efficient line will achieve an annual production volume of up to 450,000 tons of high-quality Testliner and Corrugated Medium in the basis weight range of 70 to 140 gsm. The planned design speed is 1,600m/min. The start-up of the complete production line is scheduled for Q4 2027.

Andritz Digital Factory achieves CMMI certification

International technology group Andritz has attained Level 3 certification under the prestigious Capability Maturity Model Integration (CMMI) scheme for its cutting-edge approach to software and digital product development at the Andritz Digital Factory (ADF) in Zagreb, Croatia.

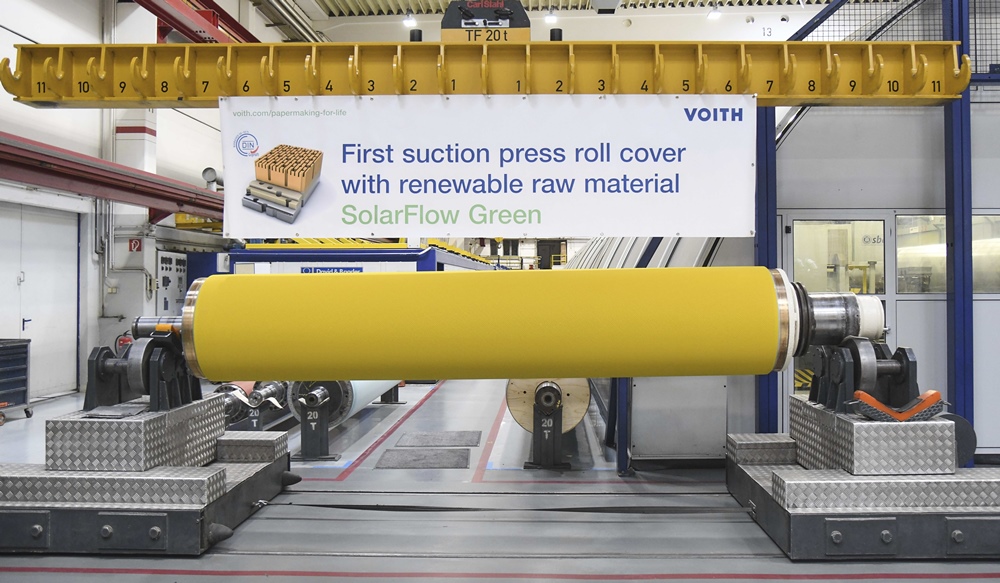

Bio-based SolarFlow Green suction press roll cover ensures more sustainable paper production

With SolarFlow Green, Voith is setting yet another standard for paper manufacturing products made of renewable raw materials. The suction press roll cover is certified according to the internationally recognized DIN CERTCO standard for bio-based products. The cover combines all the advantages of the proven SolarFlow technology while simultaneously reducing the carbon footprint. This innovation is in line with Voith’s long-standing commitment and ambitious goals to promote sustainability in both paper manufacturing and its own production.

Decarbonising the Italian pulp & paper industry

AFRY has been selected by Assocarta to define a decarbonisation strategy for the pulp and paper sector that is in line with EU framework, country-specific conditions, and technological advancements. AFRY’s assessment will outline an overall decarbonisation roadmap for the sector, pinpointing the best available technologies, regulatory and infrastructural obstacles, and competitive levers. Additionally, AFRY will provide an analysis of the pulp & paper sector in Italy, including potential scenarios to 2030 and required policies.

Andritz completes combustion system upgrade on Essity tissue machine in England

International technology group Andritz successfully completed the upgrade of the combustion system on a through-air drying (TAD) tissue machine at the paper mill of Essity in Prudhoe. This is the third upgrade of this kind that Andritz carried out for global hygiene and health company Essity.

Toscotec starts up a complete tissue line at C. Y. P. Del R. S.A. in Colombia

Colombian tissue manufacturer C.Y.P. Del R. S.A. has started up a complete Ahead 1.8 tissue line supplied by Toscotec at its mill in Risaralda. This is a repeat order for Toscotec who has successfully installed a TT SYD Steel Yankee Dryer at the same mill on PM1 in 2021.

Closed material loop: Voith intensifies efforts to recycle press felts

Recycling is a central component of Voith Paper’s sustainability strategy and forms the basis for a sustainable paper industry. With this in mind, the company is stepping up its activities in the area of reutilization and recycling of press felts in order to conserve resources, reduce waste and cut CO2 emissions.

Valmet to deliver a boiler rebuild to E.ON’s power station in Scotland, UK

Valmet will deliver a major boiler rebuild to E.ON’s Steven’s Croft biomass power station in Lockerbie, Scotland in the United Kingdom to secure trouble-free operation of the boiler for years to come. The order is included in Valmet’s orders received of the first quarter 2024. The value of the order will not be disclosed. The scheduled delivery period will be during the second quarter of 2024.

Emtec: Efficiency and Sustainability at TappiCon 2024

Emtec Electronic GmbH, manufacturer of specialized testing and measuring equipment, will give a technical program presentation and showcase its innovative product line at TappiCon 2024, one of the premier gatherings for professionals in the pulp, paper, and cardboard industry, from April 28 to May 1 in Cleveland, Ohio.

GAW receives order from Shandong Jin Tian He Paper for coating colour preparation

Shandong Jin Tian He Paper Co., Ltd. awarded GAW technologies GmbH with an order for the coating colour preparation and working stations to the new PM13 in China. The 6,320 mm wide PM13 will produce food grade folding boxboard (food quality packaging material) with a basis weight range of 170 to 400 g/m2 at a production speed of 800 m/min.

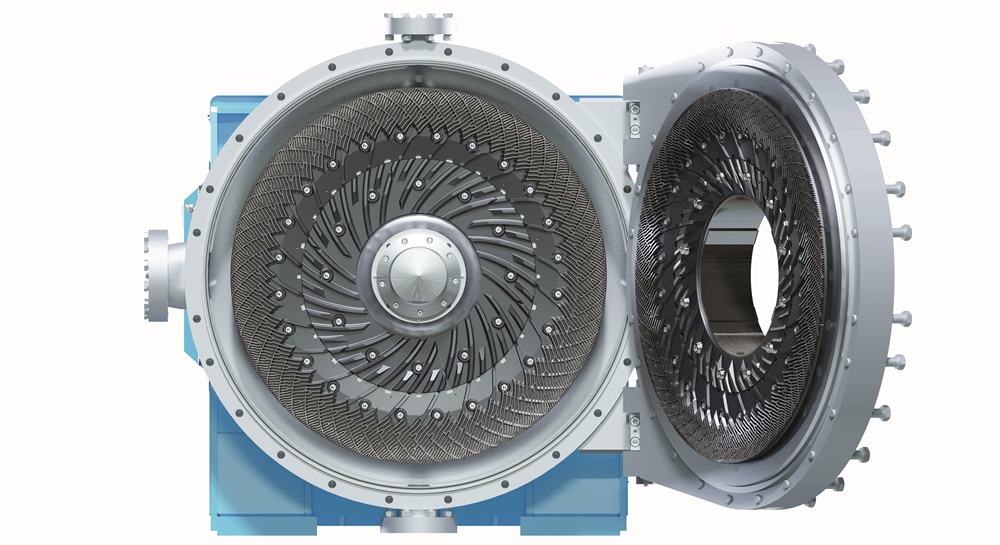

Andritz to supply a pressurized refining system for production of sustainable insulation to Switzerland

International technology group Andritz has received an order from Lignatherm AG to supply a pressurized refining system for a new insulation board production plant in Küssnacht am Rigi, Switzerland. This greenfield plant will use exclusively wood chips from local forests to produce eco-friendly insulation board.

Valmet to deliver a wide range of shutdown services to Ittihad Paper Mill

Ittihad Paper Mill (IPM) in Abu Dhabi, United Arab Emirates, has again selected Valmet as the main supplier of field services to its annual shutdown in 2024. The shutdown will take place at the end of July 2024. The order was included in Valmet's orders received of the fourth quarter 2023. The value of the order will not be disclosed.