Suppliers News

Paper Corea starts up Andritz shoe press with record line load for packaging paper in South Korea

Paper Corea Inc. has successfully started up a PrimePress X shoe press supplied by international technology group Andritz at its paper mill in Gunsan, South Korea. This marks a significant milestone, as the press features the highest line load ever installed for paper production in South Korea - an achievement that enables stronger, more durable paper and boosts production efficiency through optimized dewatering and faster machine speeds.

Toscotec delivers major rebuild for Sofidel

Toscotec is pleased to announce the successful start-up of the PM1 tissue line at Sofidel Roanne’s mill in France. This move follows a major rebuild of the tissue machine, a modernization project designed to meet one of the Sofidel's key objectives, energy savings. These efforts support the company’s long-term decarbonization and sustainability goals.

Valmet signs a two-year service agreement with FPC Tissue Spa to ensure optimal mill performance

Valmet has signed a two-year automation service agreement with FPC Tissue mill in Chile. The agreement aims to ensure optimal performance of process control and product quality on the mill’s tissue machine TM 1. The order was included in Valmet’s orders received of the third quarter 2025. The value of the order will not be disclosed.

Genera starts up Andritz pulping and stock preparation systems for sustainable packaging production

Genera, a U.S. manufacturer of sustainable packaging, has successfully started up advanced non-wood pulping and stock preparation systems supplied by international technology group Andritz. Installation of these systems is part of Genera’s large-scale expansion of its manufacturing facility in Vonore, Tennessee, where locally grown grasses are transformed into packaging solutions.

Toscotec: Proven electric energy solutions in New Delhi

Toscotec is set to showcase sustainable tissue solutions at Paperex 2025, the internationally renowned series of exhibitions and conferences focusing on paper, pulp, and allied industries. From December 3-6, Toscotec will be present at International Convention & Expo Centre (IICC) in New Delhi, India, with a dedicated booth M11 – together with Voith and BTG. Visitors can explore the latest technologies designed to accelerate decarbonization and efficiency in tissue production.

Valmet’s new waste-to-energy boiler to help Cheng Loong Corporation in Taiwan

Valmet will deliver a CFB boiler, flue gas treatment and automation system for Cheng Loong Corporation’s (CLC) Houli paper mill in Taiwan. The boiler will use various waste and biomass streams as fuel to produce electricity and heat for the mill. The new boiler is a significant investment in decarbonization of the mill as the new boiler will enable the reduction of coal usage and replaces an older less efficient waste boiler. CLC has estimated that this new boiler will reduce mill’s annual CO2 emissions by 48,000 tonnes. The order is included in Valmet’s orders received of the fourth quarter of 2025. The value of the order will not be disclosed.

Valmet launches next-generation wet end analyzer for process stability and product quality

Valmet introduces the next-generation Valmet Wet End Analyzer, designed to help paper, board, and tissue producers improve wet end processes to achieve superior product quality, improved process stability, and reduced operating costs. With new measurements and more sampling points for broader monitoring, the new analyzer provides all the key measurements for stabilizing wet end processes. A stable wet end improves product quality and process efficiency through consistent sheet formation, optimized chemical use, and reduced water and energy consumption.

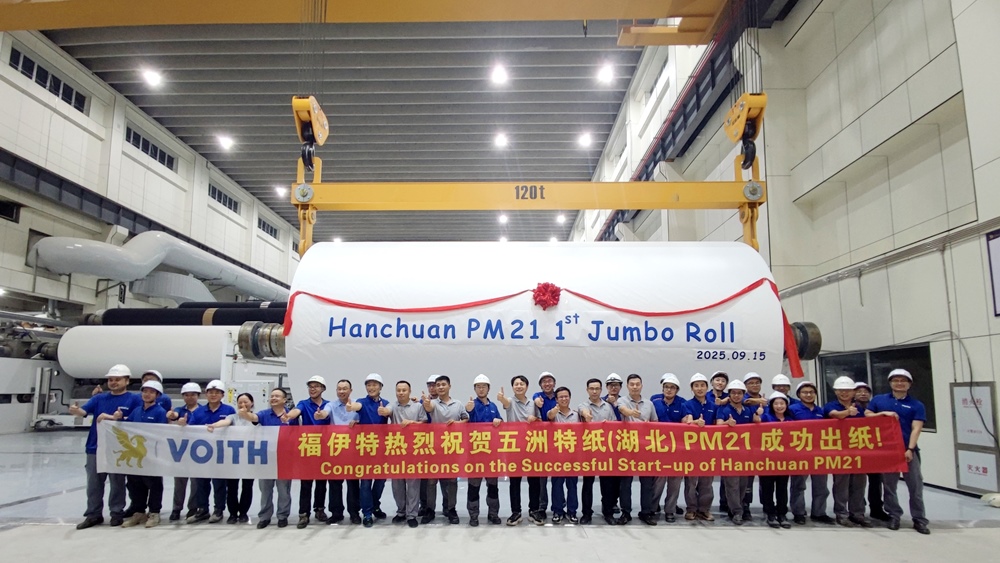

World's widest release paper production line successfully started up

Voith and Wuzhou Special Paper have successfully commissioned the new PM 21 specialty paper machine in Hanchuan, Hubei Province. It is the world's widest machine for the production of release paper. The machine, supplied entirely by Voith, demonstrates the technology group's leading role in the field of high-quality specialty papers. With a working width of 8.100 meters at the reel, the PM 21 produces around 300,000 tons of specialty paper per year with basis weights ranging from 35 to 120 g/m² – primarily lightweight release base paper.

Omya launches global sales and distribution business unit for specialty materials

Omya, the global minerals and chemicals company operating in over 50 countries, has launched a new business unit specializing in the sales and distribution of specialty materials. Headquartered in Switzerland, Omya Specialty Materials combines a comprehensive portfolio of pigments, binders, additives and life science ingredients from leading manufacturers with the company’s own extensive range of mineral-based products

New PM 71 and PM 72 increase packaging paper production at Shanying Suzhou

Shanying Suzhou Paper has successfully started paper production on its new PM 71 in Suzhou, west of Shanghai. Together with the sister machine PM 72, which recently went into operation, this double start-up marks another milestone in the partnership between Shanying and Voith. With the new machine supplied by Voith, Shanying is significantly expanding its production capacity in the premium packaging segment. In addition, the company can respond more quickly to market developments and strengthen its position in the growing market for packaging papers.

25 years of PM 9: Voith and Saica set standards in paper production

On October 12, Voith and Saica Group celebrated 25 years of the PM 9 production line at Saica in El Burgo de Ebro, Zaragoza, Spain. Today, the board and packaging machine is regarded as a true benchmark and leader in terms of operational efficiency and product quality.

Valmet’s quality control system to enhance performance at Metsä Tissue Mariestad mill in Sweden

Valmet will deliver a Quality Control System (QCS) to Metsä Tissue’s Mariestad mill in Sweden. The intelligent system will support the performance and ensure quality of the mill’s tissue machine PM 35. The order is included in Valmet’s orders received of the third quarter 2025. The value of the order will not be disclosed.