Suppliers News

AFRY will conduct a feasibility study for an E-Methane plant in Kotka

AFRY has been tasked by Arctic Sisu, a Finnish e-fuel company, to conduct a feasibility study for a large-scale e-methane production facility in Kotka, Finland. The project, planned in three phases, aims to produce 900–950 GWh of renewable e-methane annually, using CO2 from nearby pulp production as a raw material.

Voith secures contract with GDT Vietnam for cutting-edge MasterJet 4Tec headbox installation

Voith, full-line supplier to the paper industry, announces a rebuild agreement with GDT Paper Joint Stock Company in Vietnam. Voith will integrate its state-of-the-art MasterJet 4Tec headbox technology into GDT's new paper production line, setting a new benchmark for paper quality and sustainability in the industry.

Archroma launches new website to support smarter, more sustainable choices

Archroma unveiled a fully redesigned website (www.archroma.com), aimed at enhancing customer experience and accelerating the transition to more sustainable practices across the textiles, packaging, and paper value chains. Rooted in Archroma’s sustainability-driven mission, the new digital platform is designed to help manufacturers and brands make smarter, science-based decisions that reduce environmental impact. With this launch, Archroma reinforces its commitment to enabling a more sustainable future—through innovation, transparency, and accessible technology.

Toscotec to supply a complete tissue line to GrandBay Papeles Nacionales, Colombia

Toscotec will supply an Ahead 2.2 tissue line to the multi-latin company GrandBay Group at its production base in Pereira, Colombia. This marks a repeat order for Toscotec, following the successful start-up of a tissue machine at GrandBay's Guatemala site in 2023. The start-up of the new machine is planned for second semester 2025.

Trelleborg inaugurates new facility extension in Malta

Trelleborg furthers its commitment to innovation and excellence with the inauguration of its cutting-edge facility expansion in Malta. The €14 million investment in cleanrooms & equipment represents a significant milestone in supporting the fast-evolving life sciences and semiconductor manufacturing industries.

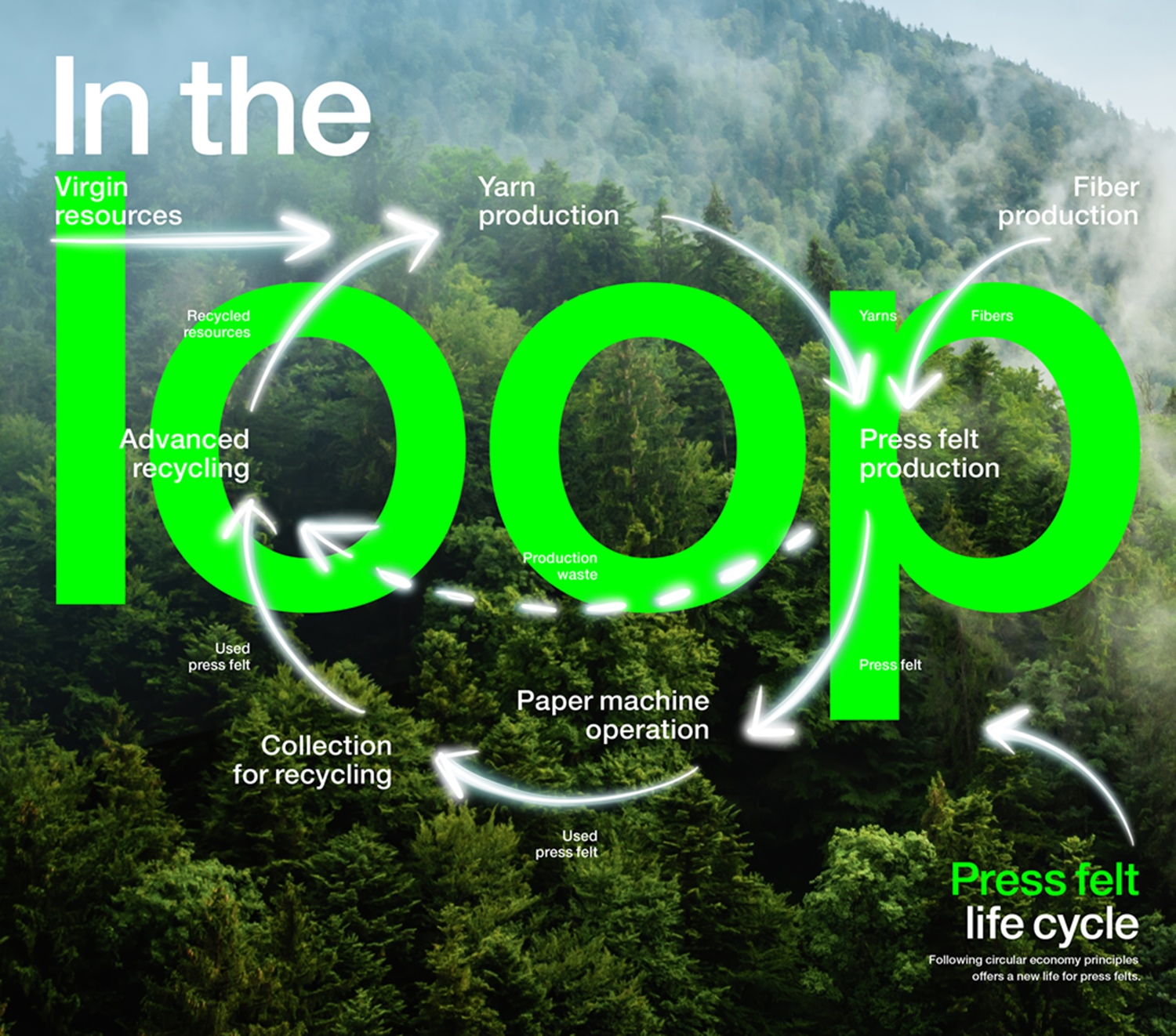

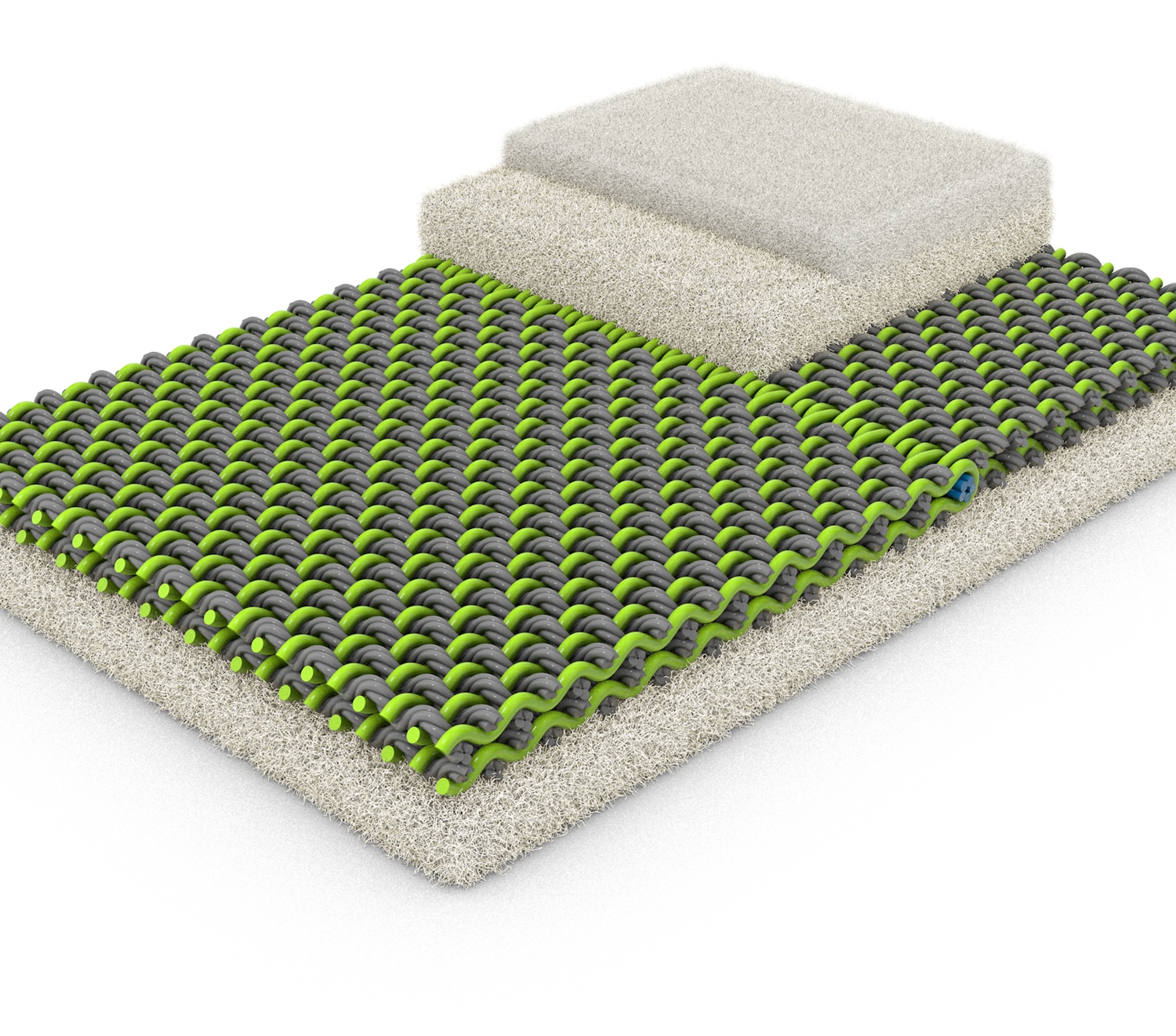

Closed recycling loop for Infinity press felts from Voith

Voith is launching an innovative recycling concept for press felts in collaboration with its partner Aquafil, enabling papermakers to drastically reduce their specific product carbon footprint. The newly developed Infinity +Green press felts and a closed recycling loop reduce Scope 3 emissions by up to 31 percent. “The majority of CO2 emissions in press felt production are related to raw material sourcing,” explains Anne Klaschka, Global Product Manager Press Felts at Voith Paper. “In addition, around 20 percent is caused by end-of-life disposal. The focus on recycling solutions is a logical consequence of this and supports papermakers in achieving their ambitious sustainability goals. We have given ourselves the task of developing an innovative concept that meets both the requirements of the industry and environmental goals.”

Valmet to deliver an energy management solution to Alva’s heat production and power plants in Jyväskylä, Finland

Valmet is to supply a Valmet DNA Energy Management solution to Alva’s new heat production units, heat accumulators and combined heat and power (CHP) plants, Keljonlahti and Rauhalahti in Jyväskylä, Finland. The new system will be integrated with the plants’ existing Valmet DNA Automation system, ensuring improved performance and reliability. This energy performance solution supports the optimization of energy production planning and helps the customer progress toward more profitable and flexible participation in electricity markets.

Ten years of XcelLine: The backbone of modern paper production celebrates a milestone

Ten years ago, Voith introduced the XcelLine and set new standards in paper production. Today, the machine is established all over the world—and has become the backbone of countless paper mills. It stands for everything that counts in a volatile market: reliability, flexibility, and innovation. Now, as the industry faces uncertainties, increasing cost pressures, and complex sustainability goals, the XcelLine emerges as a strong solution for future-proof paper production.

Saica Paper UK extends service agreement with Voith

Saica Paper UK continues the collaboration with Voith and extends the ongoing service contract for mechanical maintenance in the stock preparation running since 2019. The agreement focusses on effective maintenance planning, efficient use of resources, on-time repairs and trouble-shooting solutions.

Emtec Electronic celebrates its 30th anniversary at Zellcheming Expo

This year´s anniversary event refers to the motto “Shaping the future together. People – Technology – Innovations” and unites the pulp, paper and supplier industry in Wiesbaden from July 1 to 3. Emtec Electronic will be onsite to present its innovative measurement technology and to discuss new applications and ideas.

Andritz to acquire Diamond Power International

International technology group Andritz has signed an agreement to acquire Diamond Power International, LLC (Diamond Power) businesses, including its subsidiaries and manufacturing locations, from U.S.-based Babcock & Wilcox Enterprises, Inc. (B&W). Diamond Power is a designer and manufacturer of advanced boiler cleaning systems. The acquisition will significantly strengthen Andritz’s recovery and power boiler service business.

Successful implementation of OnEfficiency.Strength at DS Smith Witzenhausen

With over 20 installations around the globe, OnEfficiency.Strength is setting new standards in data-driven papermaking. A recent installation at DS Smith Witzenhausen shows how the use of OnEfficiency.Strength can achieve impressive results in quality stabilization. The digital solution's key impacts include savings in raw materials such as fibers and starch, as well as reductions in paper machine energy use. Using real-time data from virtual sensors to predict strength, the system controls actuators such as the jet/wire ratio, refiner, starch application and different fiber types according to the highest cost efficiency to produce the relevant paper grade in the desired specification.