Suppliers News

Toscotec starts up a tissue line at Jumbo Centre in South Africa

South African tissue producer Jumbo Centre has started up an Ahead 1.8 tissue line supplied by Toscotec at their Johannesburg facility. This is a repeat order for Toscotec after the successful installation in 2020 of another complete tissue machine at the same mill.

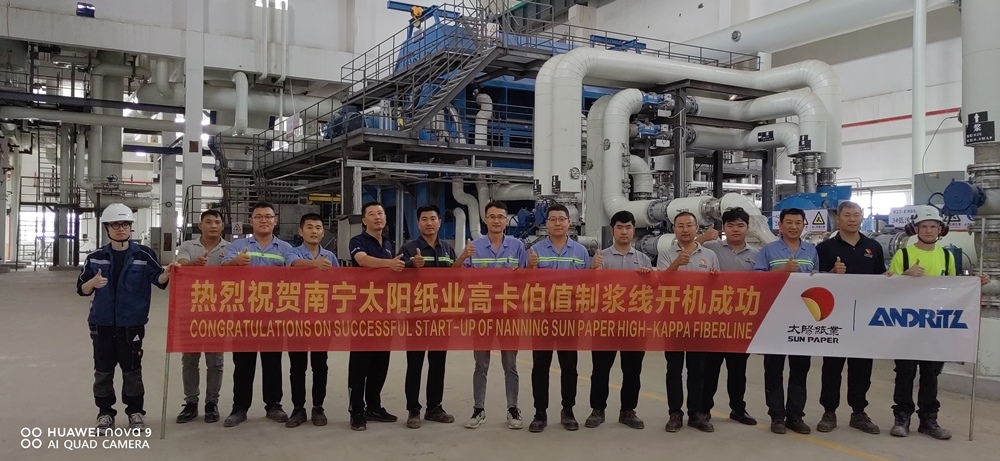

Andritz starts up largest high-kappa fiberline in China for Nanning Sun Paper

International technology group Andritz has started up a state-of-the-art, highly efficient fiberline and lime kiln plant at Nanning Sun Paper’s pulp and paper mill in Nanning, Guangxi Province, China. Zang Zijia, Project Director, Nanning Sun Paper, said, “Start-up of the fiberline and lime kiln went very smoothly. The project progressed quickly, the start-up test was completed within one month after feeding, and now the equipment is running stably. We will definitely continue working with Andritz in the future to further increase our capacity and efficiency.”

Toscotec receives second rebuild order from Ranheim Paper & Board in Norway

Norwegian cardboard producer Ranheim Paper & Board started up PM5 at its Ranheim paper mill after a dryer section rebuild supplied by Toscotec. The rebuild has been completed according to schedule. Shortly after, Ranheim Paper & Board has placed a new order with Toscotec for the second phase of PM5’s technological upgrade, which is scheduled for autumn 2024. PM5 produces greyboard and coreboard in the basis weight range from 220 to 540 gsm.

Andritz to supply the first methanol liquefaction plant to Japanese pulp industry

International technology group Andritz will supply a methanol liquefaction plant to Japanese unbleached kraft pulp producer Hyogo Pulp Industries Ltd. The plant will be installed at the Tanigawa mill to replace fossil-based support fuel with renewable liquid methanol, a by-product of the chemical recovery process. This is the first plant of its kind in the Japanese pulp industry.

Valmet has received a major order of multiple technologies from Liansheng Pulp & Paper in China

Valmet has received a major order from Liansheng Pulp & Paper (Zhangzhou) in Fujian Province in China covering multiple technology deliveries for the customer’s Zhangpu site. Valmet will supply a coated board making line (BM 2) with related automation systems, bleached chemi-thermo mechanical pulp (BCTMP) technology and two small size tissue machines (TM 5 and TM 6). In addition, Valmet will supply four tissue machine headboxes for tissue machines TM 7, TM 8, TM 9 and TM 10 at the same site.

ABB launches Real Progress campaign to accelerate global sustainability

ABB has launched its new global sustainability initiative, showcasing the power of technology and expertise to accelerate sustainability while enhancing productivity. ABB’s Real Progress campaign is a rallying call to customers, partners and suppliers, inspiring them to harness technology leadership and the solutions that exist today to amplify their own impact across process industries such as mining, metals and pulp and paper.

Toscotec to supply a complete drying section rebuild to Rexcell in Sweden

Toscotec will supply a complete rebuild of PM1’s drying section to Rexcell Tissue & Airlaid at its Skåpafors mill in Sweden. Planned for the second half of 2024, the project aims to support Rexcell to achieve substantial energy consumption reductions as part of its strong commitment to sustainability.

Suzano entrusts Andritz with maintenance for new pulp mill

Brazilian pulp producer Suzano selected international technology group Andritz to provide modular maintenance services for its new mill being built in Ribas do Rio Pardo, state of Mato Grosso do Sul, Brazil. The five-year contract covers several maintenance modules for all process islands and equipment of the new mill, which is scheduled to start up by June 2024. The modules comprise lubrication as well as predictive and inspection maintenance services, including vibration and thermographic analysis of electrical and mechanical equipment.

Successful start-up of Asia Symbol's Rugao board machine 13

At the end of October, Voith successfully started up Asia Symbol's BM 13 at Rugao, 180 km north of Shanghai, China. The state-of-the-art machine is 8.16 m wide with a design speed of 1,400 m/min and an annual capacity of around one million tons. It mainly produces high-quality white folding boxboard in the basis weight range of 170 to 400 gsm.

Toscotec supplied a dryer section rebuild to Les Papeteries de Clairefontaine

Graphic paper manufacturer Les Papeteries de Clairefontaine started up PM6 after a dryer section rebuild supplied by Toscotec at its Etival Clairefontaine mill in France. The machine produces graphic paper in the basis weight range from 60 to 100 gsm. The project was focused on PM6’s pre-dryer section for which Toscotec supplied TT SteelDryers designed for an operating steam pressure of 10 barg, as well as an upgrade of the machine frame. The associated services included the complete erection with supervision, commissioning, and start-up assistance.

ABB upgrades drive control system at Jujo Thermal paper mill in Finland

Jujo Thermal selected ABB to upgrade its drive control system at its mill in Kauttua, Finland, for improved runnability and efficiency. ABB’s scope of delivery included the provision and commissioning of the upgrade package for the existing PM2 drive control system and new drives. Jujo Thermal is a supplier of durable, direct thermal papers for labels, tickets, tags and point-of-sales use. It also generates one-side coated self-adhesive label stock and has a production volume reaching 72,000 tons per year.

Voith introduces new Pluralis Hot Stock (HS) refiner fillings

Voith is supplementing its proven Pluralis family with new Pluralis Hot Stock (HS) refiner fillings. Representing a significant advancement in refining technology, they are specifically designed to meet the demanding requirements of pulp mills and to minimize resource consumption. In addition, Pluralis HS refiner fillings can significantly improve paper quality, energy efficiency and overall pulp mill performance.