NEWS

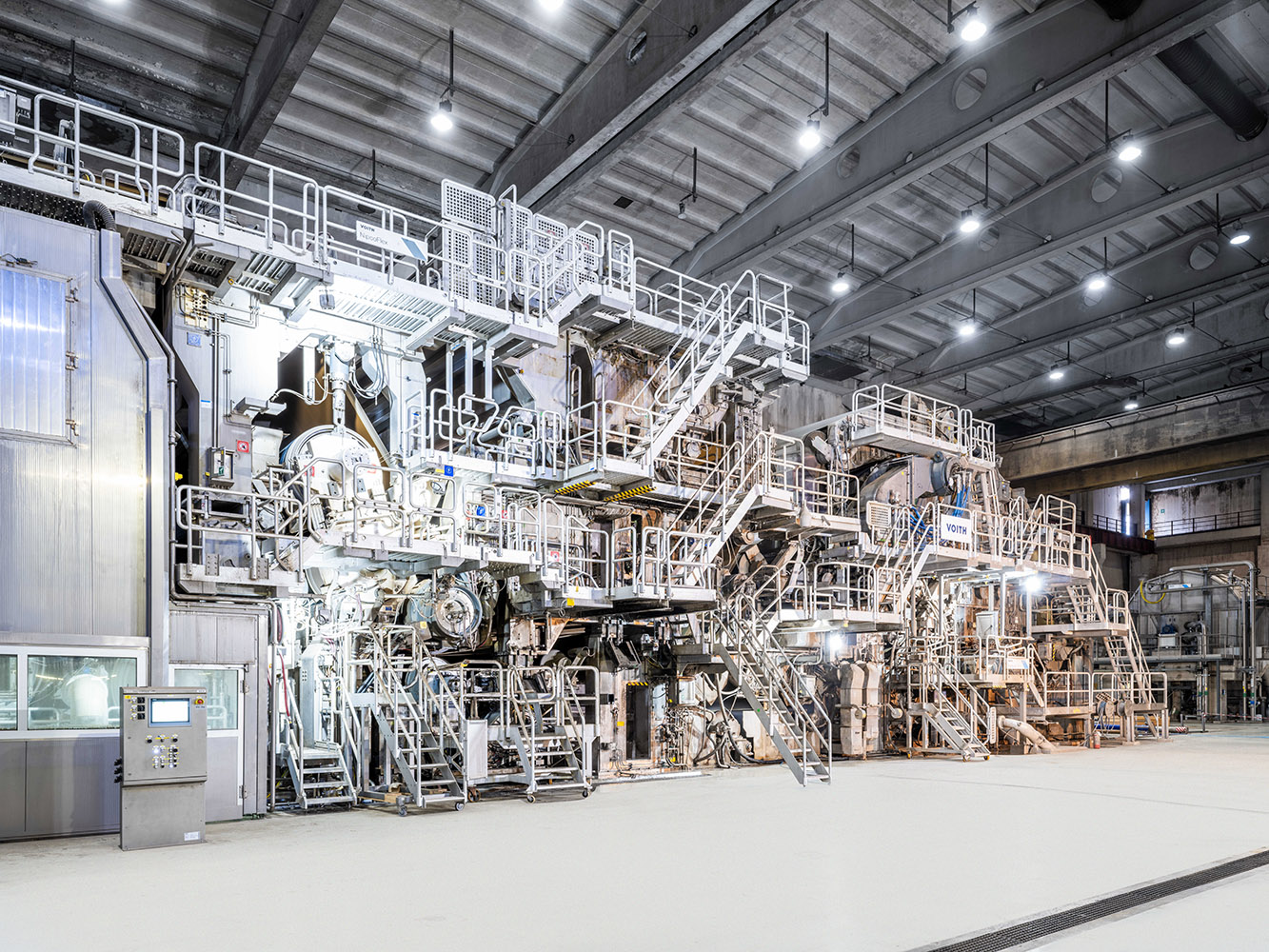

Mondi, with Voith as a key partner, brings recycled containerboard machine online

Full-line supplier Voith has supported Mondi to start up its state-of-the-art recycled containerboard paper machine in Duino, Italy, on schedule. Once fully ramped up, the machine will produce 420,000 tons of high-quality recycled containerboard annually. The mill’s product portfolio includes waste-based fluting, starting with 80 gsm, testliner from 90 gsm upwards, and paper reels from 0.95 m to 3.35 m on Mondi’s widest recycled paper machine.

“The collaboration with the Voith team went smoothly and was very trusting,” says Klaus Peller, COO at Mondi Containerboard. “Thanks to Voith's full-line approach, our interfaces were significantly reduced, which allowed for the punctual commissioning of Mondi Duino. The use of the latest technologies ensures production efficiency.”

Voith delivered a customized solution comprising a BlueLine stock preparation system, the conversion of the existing machine into an efficient XcelLine paper machine, as well as service agreements and a clothing package. The project also included the rebuild of the existing winders for processing containerboard.

“We are very proud to have completed this rebuild on time and to the customer's satisfaction,” says Martin Jauch, Senior Vice President Global Rebuilds at Voith. “This success not only confirms our leading position in the industry but is also the result of the trusting and long-standing partnership between Mondi and Voith. We will continue to work with Mondi on site beyond the rebuild to exploit the full potential of the new mill.”

The customized package covers the entire process from stock preparation to the winder. The Voith solution optimizes resource utilization through highly efficient production. The BlueLine stock preparation system enables consistent, high stock quality with optimized fiber yield and low energy consumption. An IntensaPulper with a TwinPulp detrashing system ensures efficient stock pulping. Another highlight is Voith's InfiltraDisc filter for optimum drainage.

The paper machine has been equipped with state-of-the-art technologies, including a MasterJet Pro headbox, a proven DuoFormer CBv shoe-blade former, a DuoCentri NipcoFlex press, a SpeedSizer AT for uniform film application, and a MasterReel for high-performance winding. The rebuild of the existing VariTop winder significantly increases the efficiency and productivity of the entire line.

In addition to a service and clothing package, Voith supplied and installed OnControl automation technology (DCS & MCS) for controlling and visualizing the production processes. Furthermore, the OnQuality quality control system (QCS) including ModuleJet, ModuleSteam, and ModulePro actuators and scanners for basis weight and moisture, as well as the OnView information system, were installed. These optimize product quality and stabilize the production process.

The successful project collaboration demonstrates Voith's expertise and reliability as a full-line supplier in the industry and, together with Mondi, stands for efficient and sustainable paper production.