NEWS

Solenis SmartWash helps to improve kraft pulp mill operation

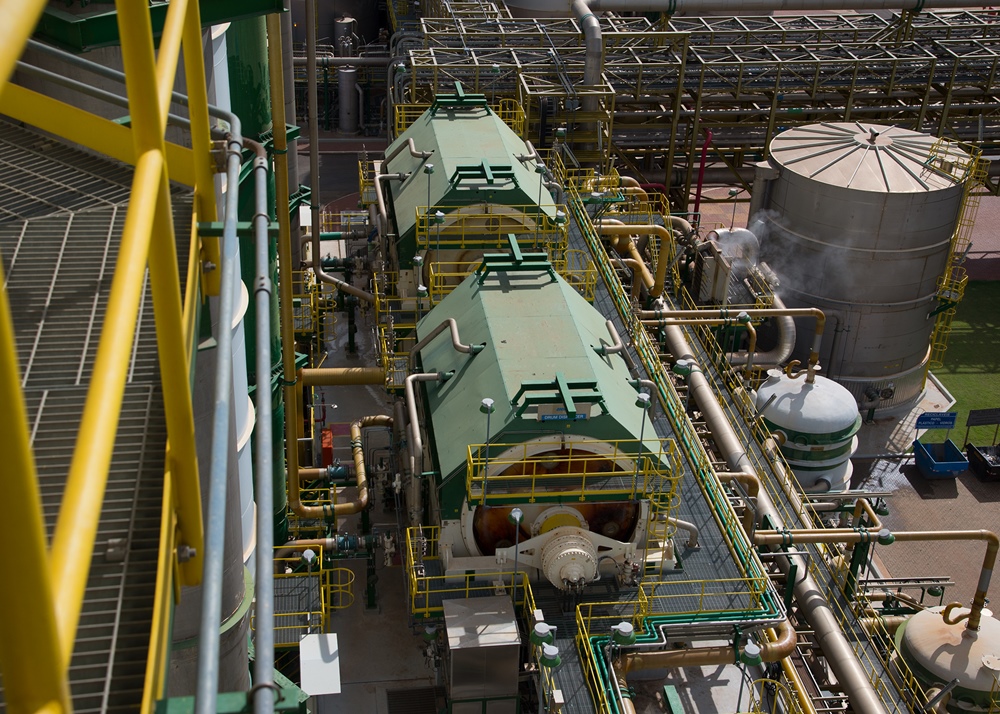

Solenis, global producer of specialty chemicals, recently implemented its SmartWash data-enhanced chemistry control solution to help a Nordic kraft pulp mill decrease costs and improve sustainability for its brownstock washing process. The customer produces pulps in their integrated mill, where top-class raw materials are needed to make high-quality end products for users requiring high levels of stability and printability. The fiber line where the SmartWash technology is being used produces both bleached softwood and hardwood pulps and has an annual capacity of >300,000 tons.

Brownstock Washing

Brownstock washing is a key process to consider in evaluating pulp mill efficiency and cost-effectiveness, as it significantly impacts the rest of the operation. Optimizing the washing process can decrease the load on the evaporation plant and reduce the need for bleaching chemicals, which leads to cleaner effluent. Overall, this helps to stabilize pulp quality and keeps unit costs low.

One way to improve the efficiency of brownstock washing is to control foaming and improve drainage, which can impact product quality, production rates and equipment efficiency. Almost every pulp mill uses a defoamer to maximize washing performance. In most cases, operators control the defoamer dosage with little or no assistance from automation technologies. However, using advanced analytics to control defoamer dosing is a better option and can be achieved with a minimum amount of mill data and a modest investment in new equipment.

Smart Defoaming

In this mill, the customer reported that it was common for operators to increase defoamer dosage levels to accommodate process problems and then forget to reset the levels. This led to overconsumption of chemicals.

To help optimize the customer’s operations, Solenis introduced its SmartWash technology, a powerful digital solution that helps customers gain economic and sustainability benefits. This technology combines defoamer chemistry with the Solenis OnGuard™ i Controller to adjust dosing based on process needs. The OnGuard i controller delivers an effective auto-adaptive dosing algorithm using only a relatively small data set. When combined with Solenis Advantage™ brownstock defoamers, SmartWash optimizes the washing process, stabilizes process conditions and reduces costs.

Using just a few dozen data tags from the pulp mill’s distributed control system (DCS), the SmartWash dosing algorithm continuously calculates new set points for each individual defoamer pump. The OnGuard i controller communicates directly with the DCS, using the predefined data tags for calculations, and then automatically sends new set points. Operators can monitor the performance of the brownstock washing and defoamer pumps on their DCS screens and can adjust dosages manually if needed. Solenis experts can also remotely adjust and fine-tune the algorithm in just a few minutes for additional service flexibility.

After successful implementation of Solenis SmartWash technology, the mill has realized significant benefits. “We have seen an increase in both pulp washing stability and efficiency,” said the pulp mill’s production engineer. “We normally change between hardwood and softwood on a regular basis, and SmartWash helps us find the optimum dosage quickly, making it possible to manage defoaming control with minimal requirements from the operators.”

Ultimately, the mill was able to limit total organic carbon (TOC) carryover to the bleaching plant, resulting in reduced usage of bleaching chemicals and providing both economic and sustainability benefits. According to the customer, this is just the beginning. “We are now working on increasing operator awareness so that they recognize when the system requires a parameter change to help lower the chemical consumption even further,” said the production engineer.

Integrated Digital Solutions

“The successful implementation of the Solenis SmartWash technology at this Nordic kraft pulp mill is a testament to the company’s commitment to innovation and sustainability, and it provides a promising example for the industry as a whole,” said Tom Hayden, Global Marketing Manager, Pulp, at Solenis. “As the demand for high-quality pulp continues to rise, the adoption of innovative and predictive technologies will be crucial for maintaining the competitiveness of the pulp and paper industry in the future.”

Solenis has been developing digital technologies for many years and has brought several unique solutions to the market. SmartWash is part of the company’s full suite of advanced digital solutions, which includes Optix™ Applied Intelligence, a paper process AI application for chemistry performance optimization and daily operator insights.

“Given the range of digital solutions available, it helps to consult with an external provider that can recommend a system or combination of systems based on a mill’s unique needs. While AI and machine learning can give operations a powerful boost in efficiency, it is not always the one and only answer,” said Andrew Ledlie, Global Director Digital Solutions at Solenis. “In many cases, Solenis engineers can create an effective digital solution that can integrate earlier-generation technologies, such as the OnGuard i controller, with more advanced technologies, like Optix. The result is a leap forward in a mill’s ability to monitor and control its key operations.”