News

Klopman and TDV Industries: A tool with EPD / Environdec certification for fabrics

Klopman and TDV Industries, a France-based company specializing in textiles for technical and military clothing, proudly announce the completion of an innovative project for the creation of an advanced tool to calculate the Life Cycle Assessment of their fabrics. The tool has obtained the prestigious and well-recognized EPD (Environmental Product Declaration) certification from Environdec.

Mondi’s re/cycle SpoutedPouch replaces plastic tubs for paint

Mondi collaborated with Sherwin-Williams, a global company in paints and coatings, to introduce re/cycle SpoutedPouch as a refill option for its concentrated paint, sold on the UK market. Leveraging the expertise in its Halle/Steinfeld plant in Germany, Mondi introduced a wider spout for easier filling and pouring, while ensuring the mono-material pouch is designed to protect its contents.

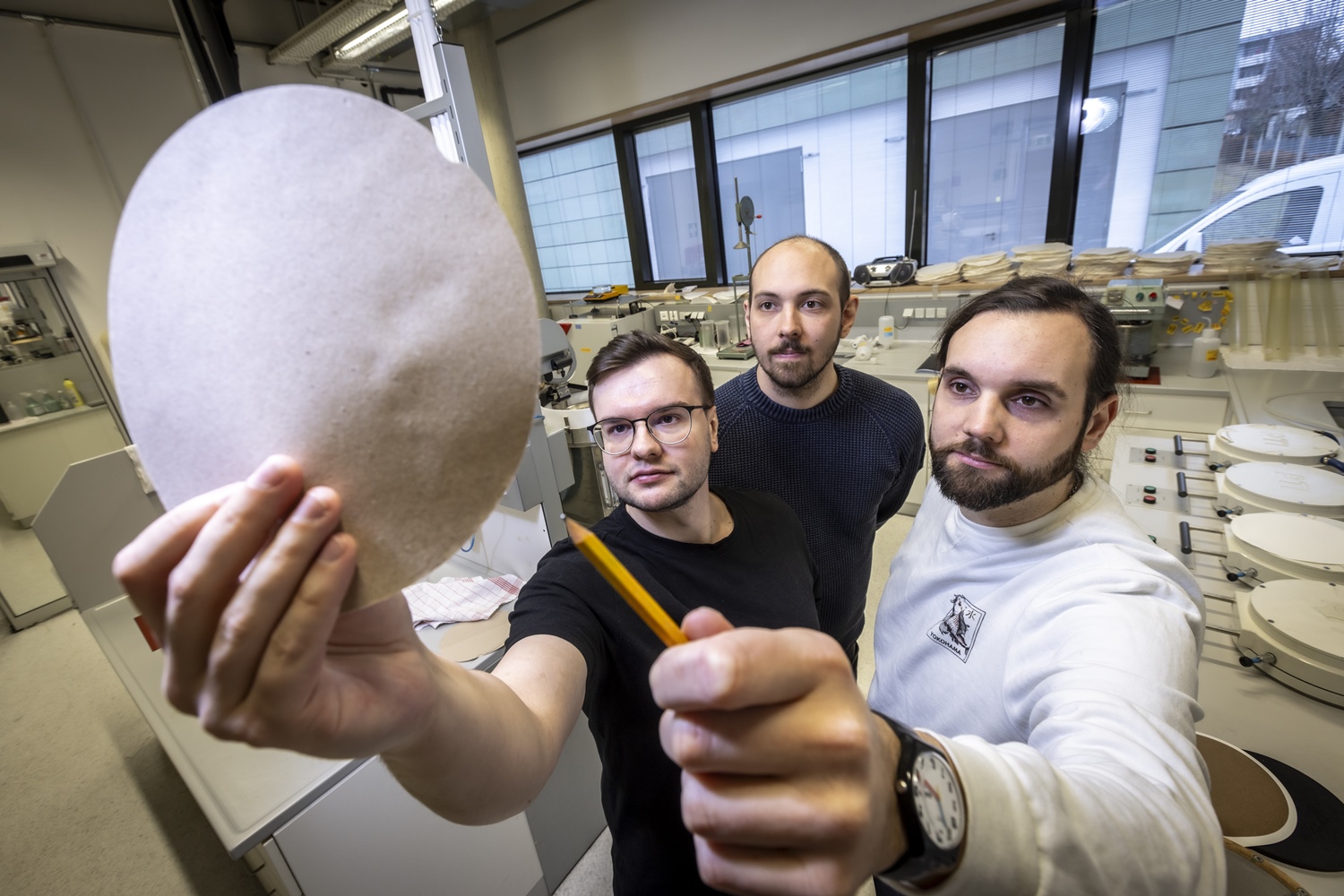

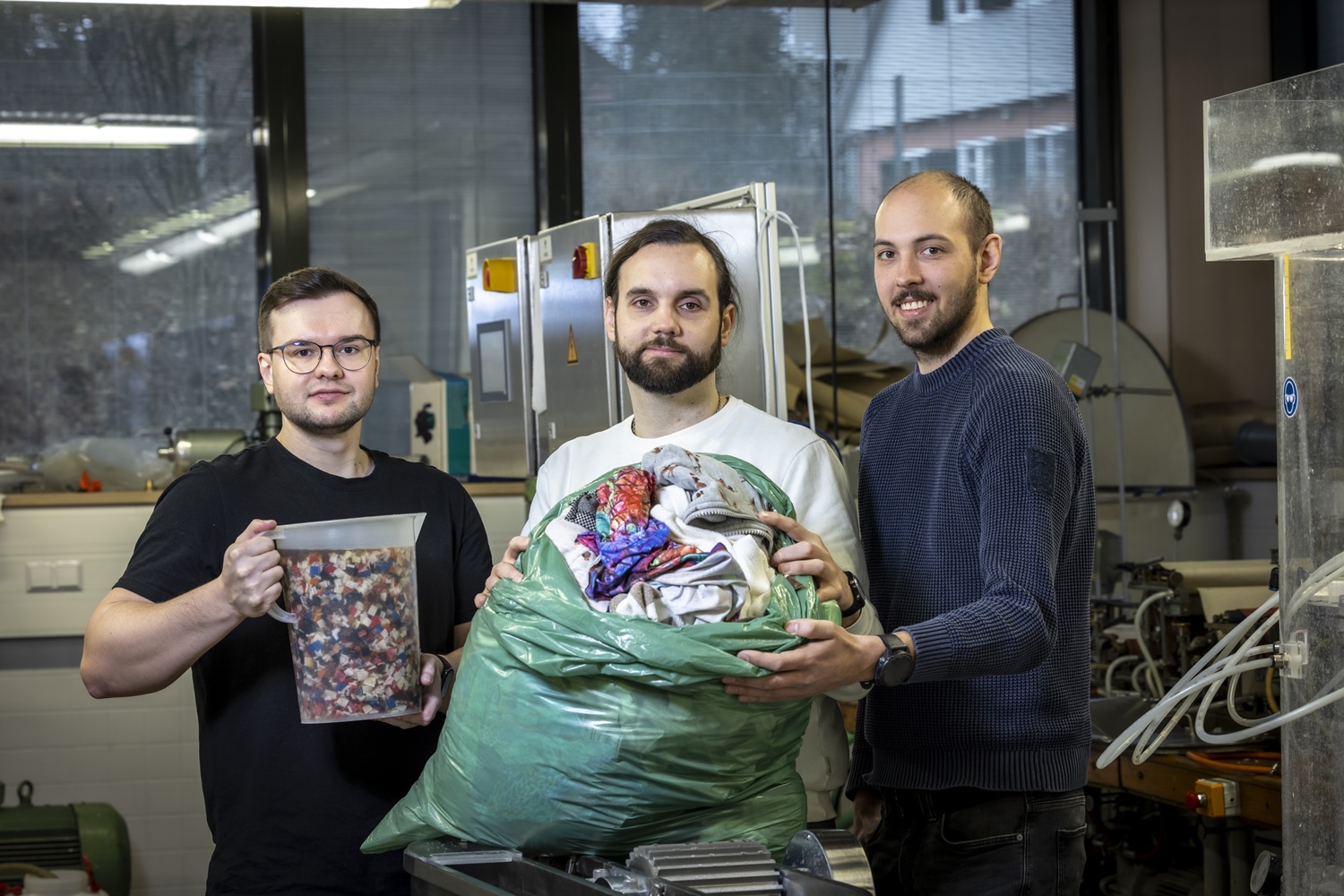

Researchers at TU Graz turn textile waste into paper

Until now, old clothes have mainly been incinerated. Using adapted processes from paper production, it is possible to recover the cellulose fibres from used clothing and use them to produce cardboard and other packaging materials. In Austria alone, around 220,000 tonnes of textile waste are produced every year, of which almost 80 per cent is incinerated. As a result, valuable raw materials are irretrievably lost. A team led by Thomas Harter from the Institute of Bioproducts and Paper Technology has come up with a sustainable solution to this problem. The researchers have developed a process to recover the fibres from cotton-based used textiles and use them to produce paper for packaging materials. Compared to conventional recycled paper, the paper with textile fibre content proves to be significantly stronger.

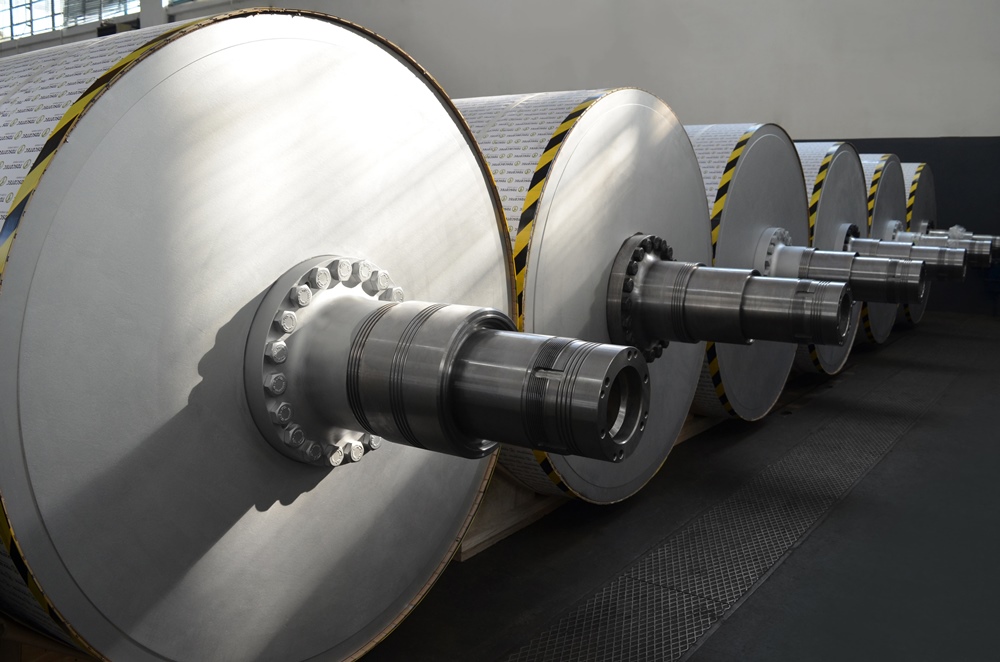

Voith to make multi-million-dollar investment in West Monroe roll service center

Voith is modernizing and expanding its roll service center in West Monroe, La., underscoring its firm commitment to the future of the paper industry and the evolving needs of customers. The expansion will be Voith Paper’s largest, most recent investment in North America.

Andritz airlay line for nonwovens production from recycled glass wool starts up at Revibat, France

International technology group Andritz supplied and recently commissioned a state-of-the-art neXline airlay system for Revibat, France. This innovative line, inaugurated at the beginning of February, enables the production of building insulation panels from glass wool waste that would otherwise be sent to landfills. With the new Andritz line, Revibat can now transform complex waste collected in the Paris region into valuable products. The patented process addresses two major challenges: giving a second life to insulation glass wool waste and reducing the carbon footprint across the entire production chain.

Klopman commits to 100% renewable energy and further reduces emissions with new innovations

Klopman, a global player in the production of high-performance fabrics for workwear, protectivewear, and casual apparel, is proud to announce a major milestone in its commitment to sustainability. From today, 100% of the energy used in all Klopman production processes will be derived exclusively from hydroelectric sources. The company is carrying out LCA – Lyfecycle Assessments on all its fabrics and the introduction of this major implementation will bring a benefit between 6 and 8% in the products Carbon Footprint (depending on the fabric).

Packaging is the new brand statement

Mondi announced the results of its sixth annual eCommerce trend report “Sustainability and its impact on packaging and online shopping choices”. This comprehensive study examines trends, attitudes and expectations regarding eCommerce and the impact packaging has on the consumer experience. The report presents data from around 6,000 consumers across Czechia, France, Germany, Poland, Sweden and Türkiye, collected via an online survey in October and November 2024. The findings offer eCommerce brands valuable insights on meeting consumer needs, including country-specific results from each of the six markets. The survey was conducted by RetailX, who also co-authored the whitepaper.

Valmet to retrofit automation at KSS Energia’s Verla 2 hydropower plant in Finland

Valmet will modernize the automation system at KSS Energia’s Verla 2 hydropower plant in Kouvola, Finland. The Valmet DNA Hydro Turbine Automation will replace an obsolete third-party system on the site. The new automation system plays a crucial role in improving the operational reliability of the hydropower plant. The order was included in Valmet’s orders received of the fourth quarter 2024. The value of the order will not be disclosed. The delivery will be taken over by the customer in December 2025.

Toscotec continues penetration of US market with new TT SteelDryer start-up

Toscotec has recently completed a dryer section rebuild including more than 10 TT SteelDryer cylinders at an American paper producer that remains confidential. This group has placed numerous repeat orders relating to four different production bases in the USA. In North America, Toscotec has installed more than 70 TT SteelDryers to date.

New CleanLine Extract360 fabric cleaning system from Voith maximizes dryer section cleanliness

With the CleanLine Extract360, full-line supplier Voith is launching a new, highly effective fabric cleaning system for the dryer section of paper machines. The innovative system is designed to overcome limitations of conventional dryer fabric cleaning, enabling excellent cleaning results, reliably removing wastewater, and extending fabric life by reducing cleaning pressure. By keeping the fabric, the cleaning system itself and the entire dryer section cleaner, the technology makes a significant contribution to the runability of the machine and reduces the risk of paper defects.

Södra delivers CLT to Gothenburg Grand Central

The construction of Gothenburg Grand Central has started, a new station building in a completely new district. Together with Hybridge, Södra is delivering 9,100 square meters of cross-laminated timber (CLT) for the building's frame. Gothenburg's new station building is a project with a clear focus on sustainability and a minimized climate footprint. The majority of the building's structure is made of wood, which is combined with recycled bricks, climate-improved concrete, and recycled steel.

Suzano reaches nominal capacity and 1 million tons of production in record time with Andritz-delivered pulp mill

Suzano has reached remarkable production milestones at its new pulp mill in Ribas do Rio Pardo, Brazil, delivered by Andritz. The world’s largest single-line eucalyptus pulp mill achieved average nominal capacity within less than six months after start-up, nearly four months ahead of schedule. Another milestone was met on January 8 when the mill’s production reached its first 1 million tons of pulp. When fully operational, the mill will have an annual production capacity of 2.55 million tons.