News

Circulose joins Spinnova’s ecosystem to accelerate technology scale‑up

Textile-to-textile recycling company Circulose joins Spinnova’s ecosystem (consortium) to help advance the scale-up of Spinnova’s technology. Spinnova has actively sought partners to accelerate commercial scale-up, and Circulose, as a key player in textile recycling, strengthens the ecosystem by providing a raw material that is in high demand across the industry.

SCA aims for 40 percent lower emissions from RoRo vessels

Starting on 1 October 2026, SCA will implement changes to its sea transport using RoRo vessels (Roll-on/Roll-off) by reducing speed, increasing vessel load factors, and adjusting how the ports in Umeå and Piteå are used. One effect of these changes is that emissions from the vessels will be reduced by approximately 40 percent.

Kesla expands twinAX shear-cutting solution to larger harvester head models

As the harvesting of small-diameter timber continues to increase worldwide - driven by growing demand for energy wood, plantation forestry, and higher productivity requirements - equipment efficiency is becoming increasingly critical. In response to these evolving operational needs, Kesla is extending the availability of its Kesla twinAX shear-cutting solution, first introduced at FinnMetko 2024, to the 24RH III and 26RH III harvester heads. Kesla twinAX is the most cost-effective wood-cutting solution on the market, particularly for operations processing large volumes of small-diameter trees.

Södra Cell Mörrum boosts pulp quality and process stability with advanced Valmet fiberline measurements

Valmet will supply two Valmet Fiberline Analyzers to Södra Cell Mörrum, Sweden, helping the mill improve process stability and product quality. The analyzers will enhance the mill’s online measurement capabilities by delivering highly accurate and reliable data to optimize the performance of both fiberlines. The order was included in Valmet’s orders received of the fourth quarter of 2025. The value of the order will not be disclosed. The delivery is scheduled for the second quarter of 2026.

Sappi Europe announces price increase for Fusion Top Liner effective April 2026

Corrugators and printers serving leading brands with high-performance packaging and displays rely on the consistent availability of premium coated and uncoated liner board. In recent years extensive internal cost and efficiency initiatives, including organisational restructuring and operational optimisation were implemented. Despite these actions, continued price erosion has created a widening gap between structural costs and the pricing levels required to maintain a sustainable and reliable supply. To address this imbalance, Sappi Europe will implement a price increase of 7% to 8% on coated and uncoated premier Fusion Liner board, effective 1 April 2026.

IFAT 2026: Failsafe conveying of aggressive chemicals in water treatment

Industrial water treatment is technically challenging, especially for pumps that convey aggressive chemicals. To address this issue, Lutz-Jesco is presenting the Peridos FXM peristaltic pump at IFAT 2026, the world's leading trade fair for environmental technologies in Munich, from May 4 to 7, 2026 (Hall 3A, Stand 222).

Kemira announces price increase for AKD wax

Kemira will implement a price increase of 10-20% for all AKD (alkyl ketene dimer) wax products, effective immediately or as contracts permit. The adjustment is driven by significantly higher costs across the AKD wax value chain.

Emtec presents its smart measurement solutions at IMPS

Once again this year, the Leipzig-based emtec Electronic GmbH will be exhibiting its innovative measuring instruments at IMPS 2026 in Munich. From March 17 to 19, the event will focus on advances in paper and board production. The International Munich Paper Symposium is opening its doors for the 34th time and welcoming experts from the paper, board and tissue industry. For years, emtec Electronic has been part of the exclusive circle of exhibitors, as the predominantly technical conference is accompanied by a renowned exhibition.

UPM collaborates with Andritz on recycling of paper machine clothing

The material solutions company UPM has entered into a collaboration with international technology group Andritz to recycle its paper machine clothing. This initiative uses innovative recycling approaches to return used fabrics and felts made from synthetic polymers to the circular economy. This avoids thermal disposal and its associated emissions while reducing the demand for fossil-based raw materials.

Mondi spices up ultra-high barrier paper packaging for Prymat

Mondi has collaborated with Prymat, the Polish dried seasoning manufacturer, to create packaging that contributes to a circular economy while protecting its aromatic spices. The partnership will see Prymat transition to new paper-based packaging, created with Mondi’s re/cycle FunctionalBarrier Paper Ultimate. This ultra-high barrier solution was chosen following extensive trials and tests, which proved it to be a sustainable alternative to conventionally non-recyclable multi-layer structures.

Sappi Europe announces a price increase for its Speciality products

Sappi Europe will increase prices for its Speciality products by €50-70/t, depending on the grade, effective on deliveries as from 1 April 2026. Despite significant internal efficiency programs and cost-saving initiatives, and major restructuring efforts, the combination of persistent cost inflation and continued price erosion has pushed current price levels to an unsustainable point for Sappi.

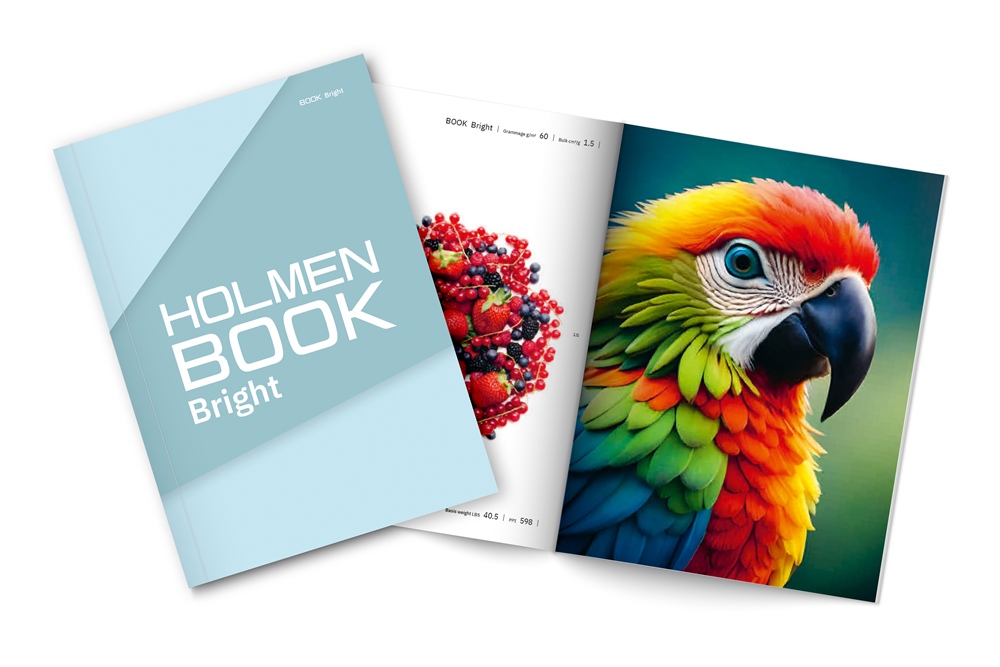

Holmen launches “a whiter book paper for a brighter future”

Holmen is introducing Holmen BOOK Bright, a new, whiter wood-containing book paper that reproduces colours with clarity and intensity. The paper offers a high level of opacity and can help reduce environmental impact across the book market. Holmen has been a renowned supplier of book paper since the early 2000s, delivering a wide-ranging portfolio to make reading as easy and pleasurable as possible. With Holmen BOOK Bright, the company is taking another major step forward in developing sustainable, high-performance materials for modern book production.