News

UPM Adhesive Materials at Labelexpo Europe

UPM Adhesive Materials, formerly known as UPM Raflatac, will be showcasing high-quality label solutions that demonstrate its adhesive material performance on its stand at Labelexpo Europe 2025. UPM Adhesive Materials has an array of label materials designed for specific end-uses including FMCG, pharmaceuticals, logistics and industrials. It will be using Labelexpo Europe 2025 as a platform to showcase these solutions that deliver reliable performance and a high level of sustainability, that connect with customer ambitions.

European Bioplastics relocates to brussels and welcomes new secretary general

European Bioplastics (EUBP), the association representing the interests of the bioplastics industry in Europe, has officially relocated its main operations to Brussels. The move reinforces the organisation’s commitment to advocacy and engagement with EU institutions, as well as expanding its network and enhancing its presence within the EU policy landscape.

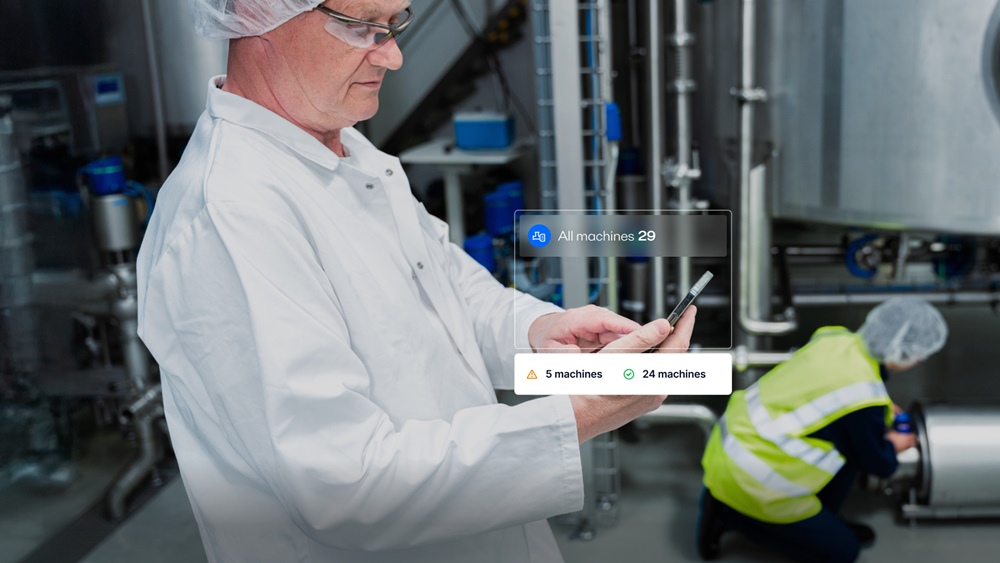

Alfa Laval launches Clariot™ for next-gen AI condition monitoring

Alfa Laval launches Clariot™, a next generation, AI-based condition monitoring solution, precision-built for hygienic process equipment to deliver more accurate analysis and support. Clariot™ monitors equipment and processes, providing actionable insights that enhance uptime and optimize resource efficiency.

Voith starts up successfully rebuilt PM 1 at Norske Skog in Golbey

Full-line supplier Voith announces the successful completion of the rebuilt Norske Skog PM 1 production line in Golbey, France. The machine is designed to produce 550,000 tons per year of recycled packaging paper at a wire width of 9,300 mm to meet the growing demand in the European market. With a design speed of 1,700 m/min, PM 1 will focus on lightweight packaging papers between 70 and 135 g/m2.

AFRY will conduct a feasibility study for an E-Methane plant in Kotka

AFRY has been tasked by Arctic Sisu, a Finnish e-fuel company, to conduct a feasibility study for a large-scale e-methane production facility in Kotka, Finland. The project, planned in three phases, aims to produce 900–950 GWh of renewable e-methane annually, using CO2 from nearby pulp production as a raw material.

Andritz selected as supplier for large carbon capture plant in Aarhus, Denmark

The utility company Kredsløb has selected international technology group Andritz as the supplier for a large carbon capture plant planned to be built in the Danish city of Aarhus. The project aims to capture approximately 435,000 tons of CO2 annually from the flue gases of a district heating facility, significantly contributing to Aarhus’ goal of becoming CO2 neutral and Denmark’s broader climate targets.

Voith secures contract with GDT Vietnam for cutting-edge MasterJet 4Tec headbox installation

Voith, full-line supplier to the paper industry, announces a rebuild agreement with GDT Paper Joint Stock Company in Vietnam. Voith will integrate its state-of-the-art MasterJet 4Tec headbox technology into GDT's new paper production line, setting a new benchmark for paper quality and sustainability in the industry.

Archroma launches new website to support smarter, more sustainable choices

Archroma unveiled a fully redesigned website (www.archroma.com), aimed at enhancing customer experience and accelerating the transition to more sustainable practices across the textiles, packaging, and paper value chains. Rooted in Archroma’s sustainability-driven mission, the new digital platform is designed to help manufacturers and brands make smarter, science-based decisions that reduce environmental impact. With this launch, Archroma reinforces its commitment to enabling a more sustainable future—through innovation, transparency, and accessible technology.

Toscotec to supply a complete tissue line to GrandBay Papeles Nacionales, Colombia

Toscotec will supply an Ahead 2.2 tissue line to the multi-latin company GrandBay Group at its production base in Pereira, Colombia. This marks a repeat order for Toscotec, following the successful start-up of a tissue machine at GrandBay's Guatemala site in 2023. The start-up of the new machine is planned for second semester 2025.

Trelleborg inaugurates new facility extension in Malta

Trelleborg furthers its commitment to innovation and excellence with the inauguration of its cutting-edge facility expansion in Malta. The €14 million investment in cleanrooms & equipment represents a significant milestone in supporting the fast-evolving life sciences and semiconductor manufacturing industries.

Research on carbon alance receives nearly SEK 9 Million from Södra’s Research Foundation

With the goal of strengthening the forest’s role in climate transition, Södra’s Research Foundation is investing SEK 8.75 million in seven research projects. The projects range from soil and growing forests to innovative solutions contributing to the green transition. The theme of this spring’s call was carbon balance, referring to the relationship between how much carbon dioxide is released into the atmosphere versus how much is absorbed and stored in, for example, forests, soil, and wood products. It is a critical area in efforts to combat climate change. To reduce emissions and increase carbon uptake, more knowledge is needed about how carbon flows through both natural and human-made systems.

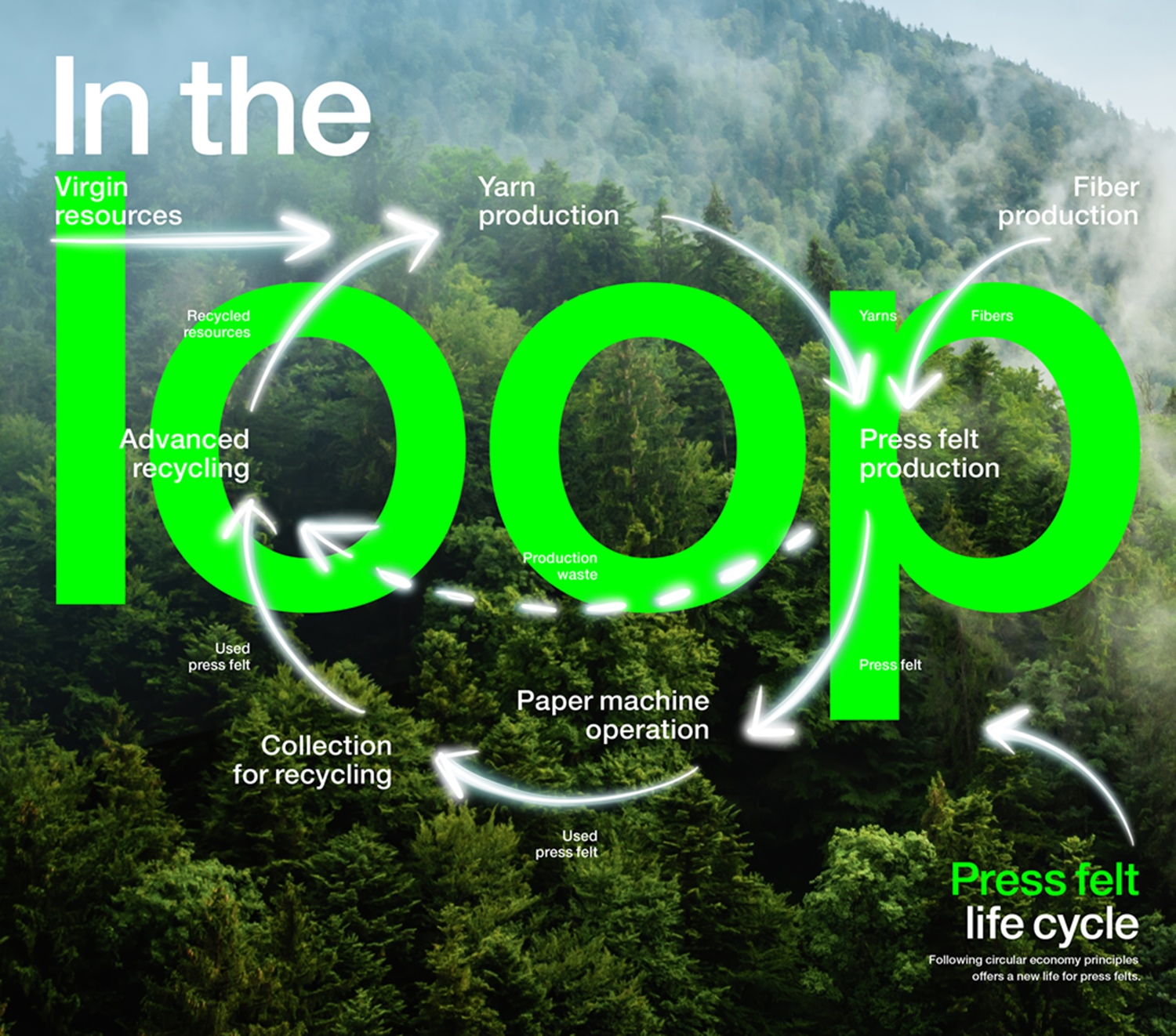

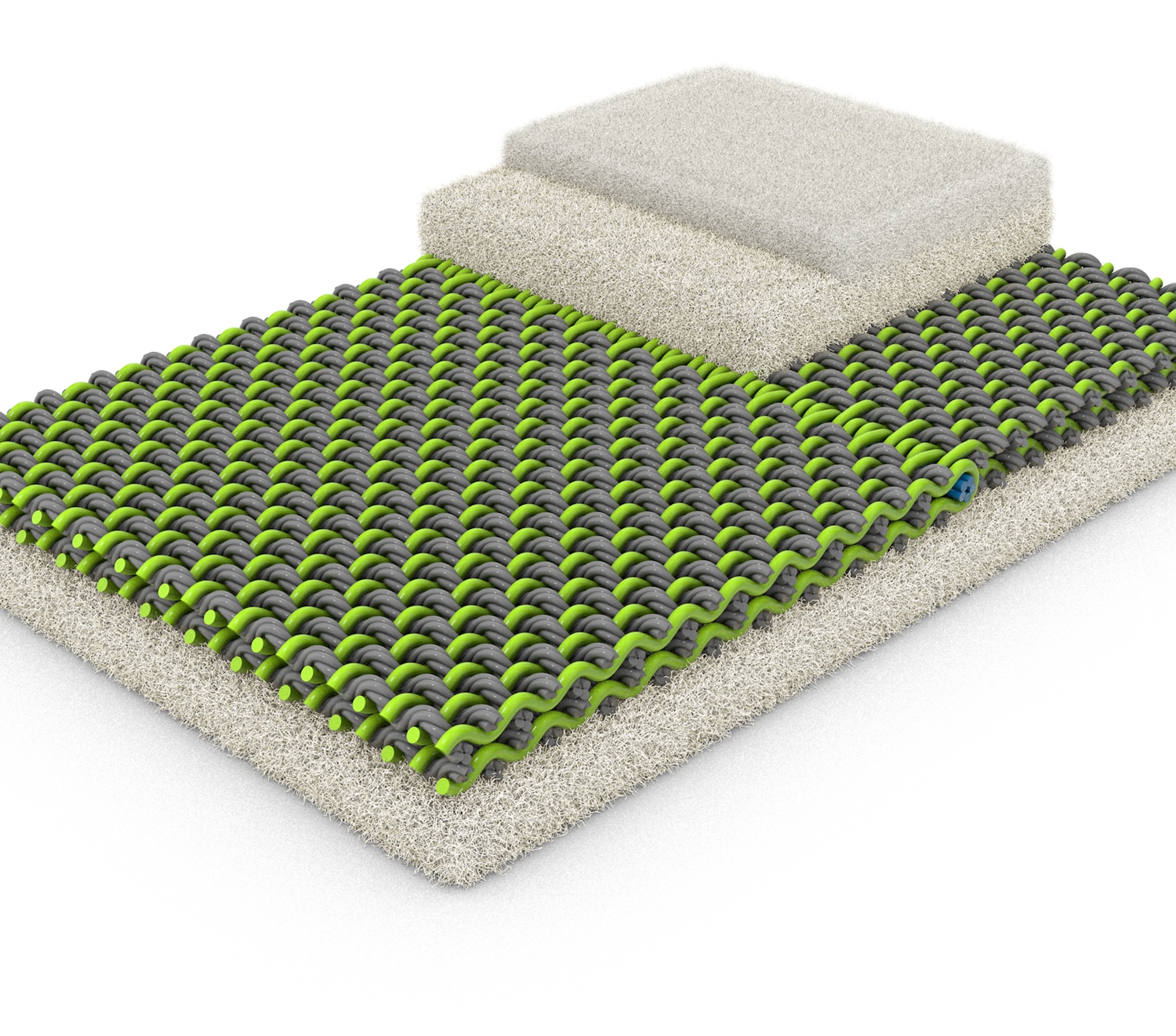

Closed recycling loop for Infinity press felts from Voith

Voith is launching an innovative recycling concept for press felts in collaboration with its partner Aquafil, enabling papermakers to drastically reduce their specific product carbon footprint. The newly developed Infinity +Green press felts and a closed recycling loop reduce Scope 3 emissions by up to 31 percent. “The majority of CO2 emissions in press felt production are related to raw material sourcing,” explains Anne Klaschka, Global Product Manager Press Felts at Voith Paper. “In addition, around 20 percent is caused by end-of-life disposal. The focus on recycling solutions is a logical consequence of this and supports papermakers in achieving their ambitious sustainability goals. We have given ourselves the task of developing an innovative concept that meets both the requirements of the industry and environmental goals.”