News

Gmund Paper wins German Sustainability Award 2026

On the 5th of December 2025, Gmund Paper received the German Sustainability Award 2026 in the paper, cardboard, paperboard category. The independent expert jury awards the prize to companies that have made a particularly impressive contribution to transformation in their respective industries, based on transparent jury rules, intensive research, publicly available information and the expertise of the jury.

Billerud invests in the next level of fluting performance at Gruvön

Billerud is strengthening its position in the premium Containerboard segment through a targeted investment at its Gruvön mill. A new headbox installation on the paper machine will elevate the company’s flagship product, Billerud Flute®, to new levels of strength, quality consistency, and performance.

Next-generation Valmet IQ Web Monitoring System for process visibility

Valmet introduces the renewed IQ Web Monitoring System (WMS), designed to elevate quality and efficiency in pulp, paper, tissue, as well as paper and board converting industries. The new WMS delivers exceptional image quality through the most compact design and industry-leading illumination technology.

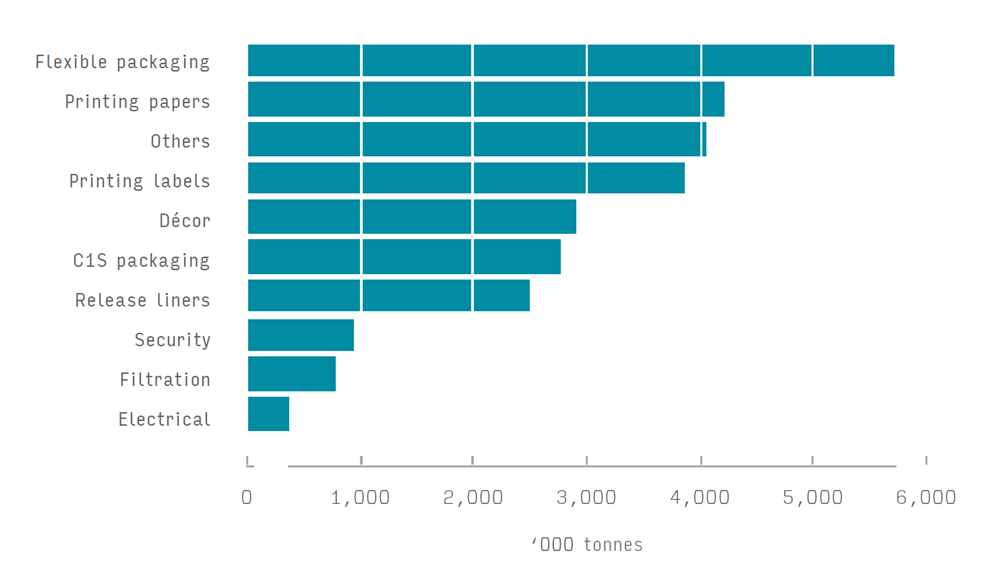

Smithers forecasts 2.1% growth rate for specialty papers market

A total of 28.1 million tonnes of specialty papers will be consumed in 2025, according to Smithers. Competing factors will push overall consumption to 31.3 million tonnes in 2030, equivalent to a compound annual growth rate (CAGR) of 2.1% for the next 5 years. The latest market report from Smithers – The Future of Specialty Papers to 2030 – tracks consumption and technology trends across 45 separate specialty paper grades worldwide, by region and by country.

SCA on CDP’s sustainability A-List 2025

SCA has earned a place on the Carbon Disclosure Project’s (CDP) prestigious A-List for 2025 – the highest possible rating – in the categories of Climate and Forests. The award signifies that SCA ranks among the global top performers in terms of transparency, strategic sustainability work, and concrete actions in these areas. In this year’s CDP evaluation, SCA is placed on the A-List in the Climate and Forests categories.

Feldmuehle draws a line after more than 120 years

“In recent years, our company has made high-quality, capital-intensive investments in sustainability and energy efficiency. We have optimised and modernised processes, committed ourselves to training the next generation, developed new products and reduced our costs – all in a highly competitive environment.”

(A statement by Feldmuehle GmbH, Uetersen, Germany.)

Sappi and UPM propose new Joint Venture company for graphic paper business

Sappi Limited (“Sappi”) and UPM-Kymmene Corporation (“UPM”) have announced the signing of a non-binding letter of intent to form a non-listed, independent 50/50 Joint Venture for graphic paper. This Joint Venture will bring together Sappi’s European Graphic Paper business with UPM’s Communication Papers business in Europe, the UK and the US. The transaction will be subject to the fulfilment of a number of regulatory and other conditions, including shareholder approval.

Paper Corea starts up Andritz shoe press with record line load for packaging paper in South Korea

Paper Corea Inc. has successfully started up a PrimePress X shoe press supplied by international technology group Andritz at its paper mill in Gunsan, South Korea. This marks a significant milestone, as the press features the highest line load ever installed for paper production in South Korea - an achievement that enables stronger, more durable paper and boosts production efficiency through optimized dewatering and faster machine speeds.

Toscotec delivers major rebuild for Sofidel

Toscotec is pleased to announce the successful start-up of the PM1 tissue line at Sofidel Roanne’s mill in France. This move follows a major rebuild of the tissue machine, a modernization project designed to meet one of the Sofidel's key objectives, energy savings. These efforts support the company’s long-term decarbonization and sustainability goals.

Cooperative organisations strengthen the Swedish economy

A new report from Svensk Kooperation shows that cooperative enterprises in Sweden have increased their turnover by 27 percent over the past decade and now account for around ten percent of GDP. Södra is one of the largest players, contributing to a resilient and sustainable forestry sector – where members have influence and share in the value created.

Valmet signs a two-year service agreement with FPC Tissue Spa to ensure optimal mill performance

Valmet has signed a two-year automation service agreement with FPC Tissue mill in Chile. The agreement aims to ensure optimal performance of process control and product quality on the mill’s tissue machine TM 1. The order was included in Valmet’s orders received of the third quarter 2025. The value of the order will not be disclosed.

UPM Adhesive Materials and GeBE reach high-performance milestone

A recent long-term test conducted by GeBE Elektronik und Feinwerktechnik GmbH, a provider of thermal printing systems, using UPM Raflatac OptiCut™ RL54 linerless label material has reached an impressive milestone: two million cuts without the need for blade cleaning. This achievement highlights the exceptional processing properties of the OptiCut adhesive, which was specifically engineered to minimize residue and ensure smooth operation in high-speed linerless cutter systems.