NEWS

MM Group orders continuous cooking plant from Andritz

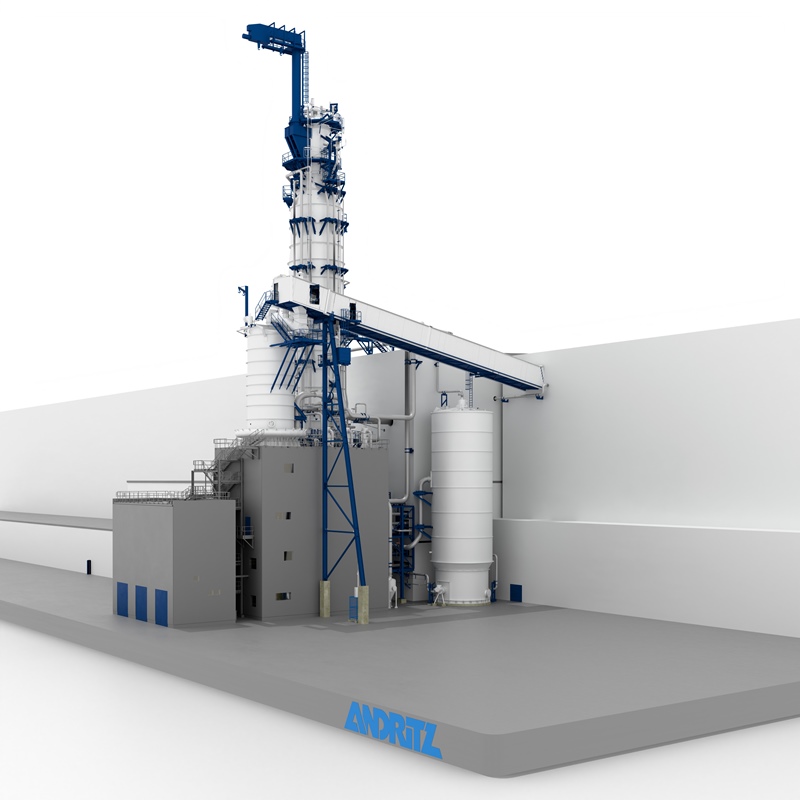

International technology group Andritz has received an order to supply a new cooking plant to MM Group’s integrated pulp and paper mill in Kwidzyn, Poland, supporting the mill’s major sustainability and energy-efficiency upgrade program. Andritz will replace the mill’s batch digester cooking plant with a LoSolids continuous cooking plant designed to switch between softwood and hardwood pulp production. This investment will significantly reduce energy consumption and CO2 emissions at the MM Kwidzyn mill.

Filip Drofiak, Chairman of the Board of MM Kwidzyn, comments: “By adopting this advanced technology, we can considerably lower our energy consumption while gaining the flexibility to process both softwood and hardwood. These improvements support our commitment to sustainability and strengthen MM Kwidzyn’s competitive edge and energy independence, ensuring we remain at the forefront of board, paper, and pulp production.”

Andritz will supply a single-vessel digester enabling homogeneous cooking and process flexibility, as well as a Turbofeed chip feeding system with new Diamondback chip bin that maximizes chip presteaming and pulp quality. The delivery also includes a vapor reboiler to improve digester heat recovery and minimize odorous gas emissions. Start-up is scheduled for the fourth quarter of 2026.

MM Kwidzyn is one of Europe’s largest producers of premium virgin fibre cartonboard for pharmaceutical and luxury packaging, packaging kraft papers (PKP), uncoated fine papers (UFP) for office and offset printing, as well as pulp.