NEWS

Voith presents its vision for future user interfaces

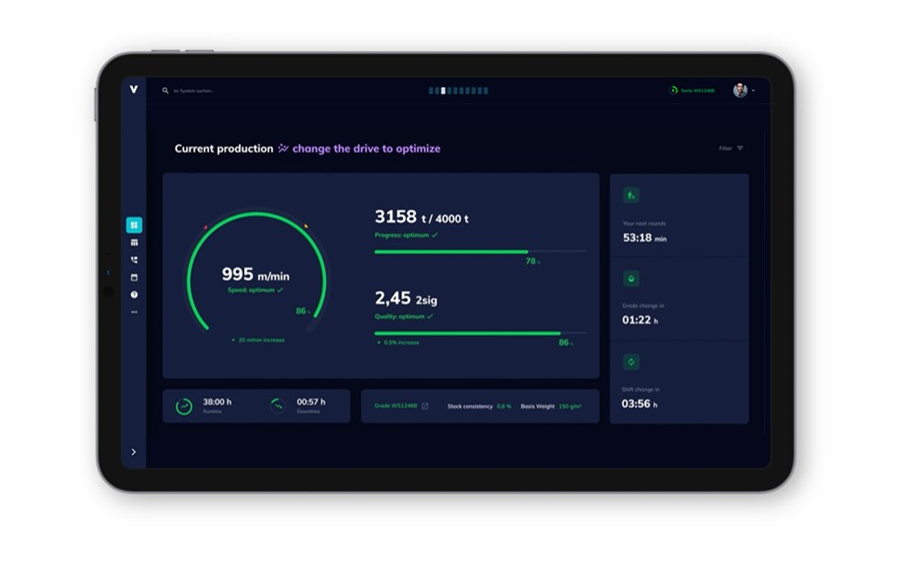

Voith presents its vision for future user interfaces with paper machines. Developed for the paper production of tomorrow, the innovative user interface significantly increases plant productivity, ensures paper quality and reduces operating costs.

Based on artificial intelligence and the latest digital technologies, Voith’s interface design significantly simplifies plant operation and maintenance and increases the degree of networking. As a full-line supplier, Voith will introduce the user interface across the entire papermaking process from stock preparation to reeling. The individual conditions on site will be flexibly taken into account. In addition, the new user interface convinces with an appealing design.

“Voith's vision consistently pursues the goal of an innovative user interface with maximized operating efficiency and minimized complexity,” explains Jürgen Abraham, President Products and Services and Digital Business Officer at Voith. “The new user interface provides a comprehensive overview of all relevant parameters with integrated dialogue and optimization functions. This means that machine downtimes can be efficiently avoided thanks to faster response times and more targeted interventions. In addition, resources and operating costs are significantly saved, while production capacity is increased at the same time. The positive results are clearly visible from the first application.”

Many new smart capabilities and digital solutions are integrated into the future interface, providing an excellent user experience. With the new design, users can see at a glance all the information and key performance indicators (KPIs) relevant to their work. This allows the operator to use artificial intelligence to intuitively optimize production settings, assign tasks individually and track them. Guided operating steps prevent information overload and incorrect operation. At the same time, smart functions optimize communication and ensure a smooth process. After shift handover, all data is archived so that a complete handover and documentation can take place. Voith developed the new concept together with the digitalization agency Ray Sono.

Latest digitization solutions from the Papermaking 4.0 portfolio

The new user interface with a modern style guide is part of Voith's design study for the paper production line of the future, in which digital innovations are used to significantly increase the competitiveness, efficiency and speed of paper production. As a leading provider of 4.0 applications, Voith already offers forward-looking and modular digitalization solutions for optimizing paper production. Intelligent technologies combine efficiency increases with ambitious sustainability goals by saving water, energy and fiber. In the process, intelligent hardware and software solutions are continuously being further developed. One of the latest developments, for example, is the OnEfficiency.BreakProtect system. With the help of artificial intelligence, this system on the OnCumulus IIoT platform will predict breaks in good time. The revolutionary digitalization technology thus makes it possible to minimize cost-intensive downtimes.

Under the following link you can find more information about the future user interface: https://voith.com/corp-en/industry-solutions/papermaking/papermaking-vision.html#144435.