NEWS

PulpEye participates in Industry 5.0 research project

Industry 5.0 is a recently started pilot project in which PulpEye is one of the participants. It is a two-year project aiming at finding more efficient and secure ways for remote monitoring of mills’ processes. Industry 5.0 is financed by the Swedish strategic innovation programme “Process Industrial IT and Automation”, and the participating partners.

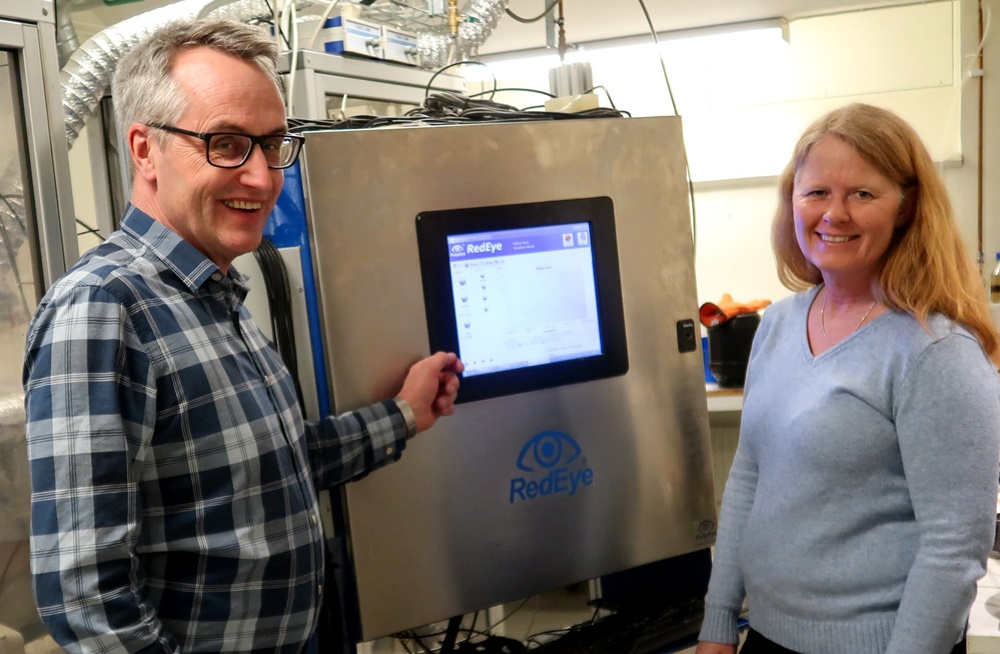

The project consists of five working packages: RedEye as on-line analyser for an HTL pilot at RISE Processum concerning IT security, user interface, business model and application at a customer. PulpEye is involved in all five working packages. Hydrothermal liquefaction, HTL, is a thermal depolymerization process used to convert wet biomass and other macromolecules into crude-like oil under moderate temperature and high pressure.

“RISE Processum’s HTL pilot is suitable to be used in this very interesting project,” says Öjvind Sundvall, MD at PulpEye. “It is an interesting biorefining process in which PulpEye’s RedEye analyzer module has not been used before. However, as our RedEye analyzer normally is used for analysis of cooking liquor it is a good fit in this project. The project will also involve trials in one of RISE Processum’s bioreactors.”

“This is a very interesting project with a clear win-win situation,” says Yvonne Söderström Nordin, Senior Project Manager at RISE Processum. “We will get much faster analyses from the pilots and PulpEye will get access to a large amount of data in a safe and efficient way. In the long run a successful project will open the doors to remotely monitor and control mills in an efficient way globally.”

“As IT security is a crucial part of the project and necessary if the idea of Industry 5.0 will take off. It is therefore an advantage that both PulpEye and RISE Processum are located at the same site, High Coast Innovation Park, making quick and close contacts during the project possible. One result we hope to achieve is that this technology can be used for upscaling of pilot plants in which PulpEye analyzers could be a natural part,” Öjvind Sundvall finishes.

Industry 5.0 is carried out within the strategic innovation program “Process Industrial IT and Automation”, a joint venture by Vinnova, Formas and the Swedish Energy Agency. The project partners are PulpEye, RISE Processum, the Nordic telecom provider Telia, BillerudKorsnäs and Kondor Processoptimering.