NEWS

New ABB Ability™ digital solution continuously monitors paper machine drive health to prevent failures and boost productivity

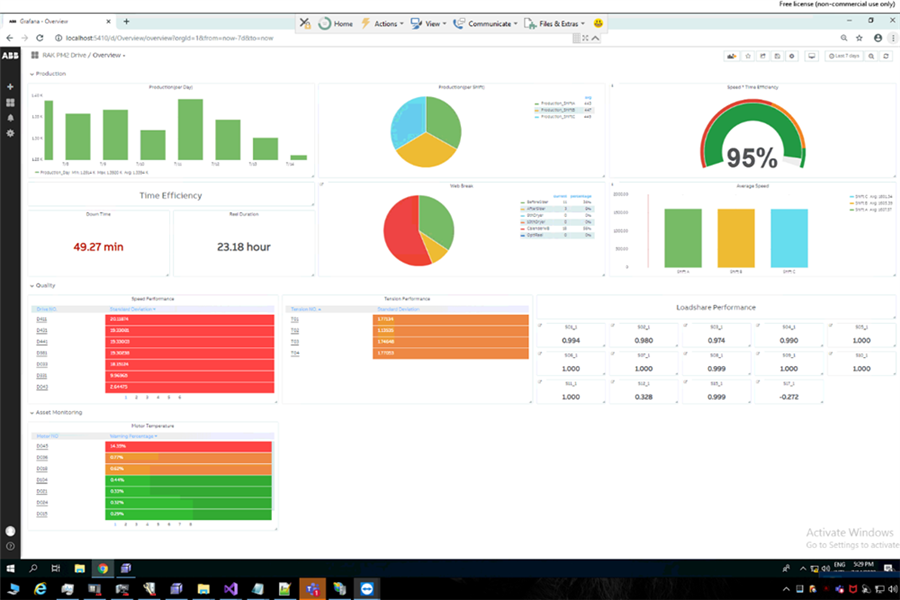

ABB launched Paper Machine Drives Performance, a pioneering digital data analysis solution providing pulp and paper manufacturers with detailed insights into their drive system health to improve runnability and reliability, reduce sheet breaks and ultimately improve paper quality.

Paper Machine Drives Performance is the only continuous monitoring, drive-specific digital service that leverages a digital twin to better model and evaluate system drive control performance. Applying an advanced calculation engine to critical system data permits near real-time performance monitoring for web tension, speed control, draw and load share. This in turn enables drive system control optimization, faster troubleshooting and more informed asset decisions?.

The system also provides advance warnings of potential failures and maintenance alerts, which enable mills to undertake predictive maintenance, reducing unplanned downtime and higher maintenance costs.

“Customers are always seeking better ways to understand their drive system health while efficiently identifying the root cause of any issues,” said Sanath Kumar, Global Product Manager for Paper Machine Drives, ABB. “Our new solution is the only available offering that specifically monitors paper machine drive control performance to provide near real-time detail on performance status, plus predictive alerts and root cause insights to optimize control and leverage predictive maintenance strategies.”

Removing the need for manual data collection, Paper Machine Drives Performance leverages the ABB Ability™ platform to collect and analyze a breadth and depth of data that would otherwise be unachievable. Part of the ABB Ability™ Performance Service for paper mills family, the service follows ABB’s proven ‘diagnose, implement, sustain’ methodology, helping grow and optimize performance and is delivered via ABB Ability™ Collaborative Operations.